Performance Characteristics

-

01High Gelatinization Degree and Excellent Nutrient Absorption+It is equipped with a high-efficiency combined three-shaft conditioner, and its unique water-steam co-injection structure ensures that water, steam and materials are fully mixed; the special pick structure and arrangement enhance beating performance on material, improve the filling rate, extend the conditioning time, and improve the pre-gelatinization effect in conditioner; at the same time, the screw parameters and configuration are optimized, and the starch gelatinization degree can reach as high as 95%.

01High Gelatinization Degree and Excellent Nutrient Absorption+It is equipped with a high-efficiency combined three-shaft conditioner, and its unique water-steam co-injection structure ensures that water, steam and materials are fully mixed; the special pick structure and arrangement enhance beating performance on material, improve the filling rate, extend the conditioning time, and improve the pre-gelatinization effect in conditioner; at the same time, the screw parameters and configuration are optimized, and the starch gelatinization degree can reach as high as 95%. -

02Hygiene and Safety to Protect Pet Health+Brand new design with a perforated base for improved hygiene, featuring a stable structure that is easy to clean and maintain. Optional full stainless steel barrels eliminate sanitation dead corners, making them easy to clean and disinfect, and ensuring compliance with food safety standards.

02Hygiene and Safety to Protect Pet Health+Brand new design with a perforated base for improved hygiene, featuring a stable structure that is easy to clean and maintain. Optional full stainless steel barrels eliminate sanitation dead corners, making them easy to clean and disinfect, and ensuring compliance with food safety standards. -

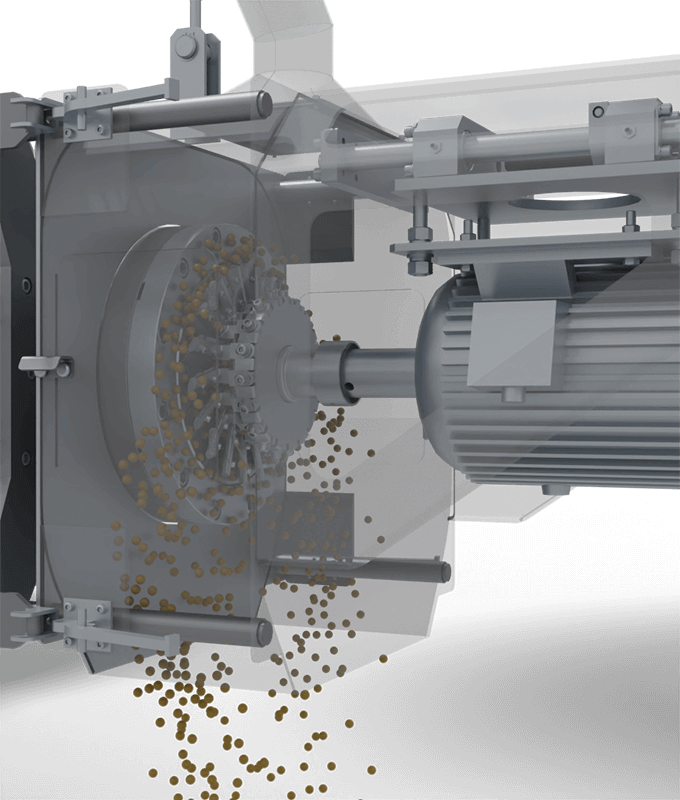

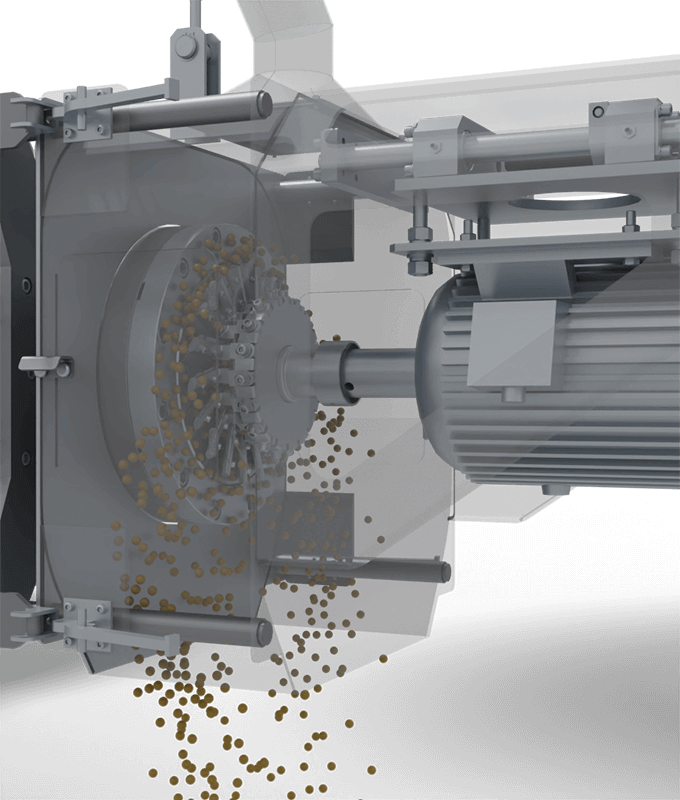

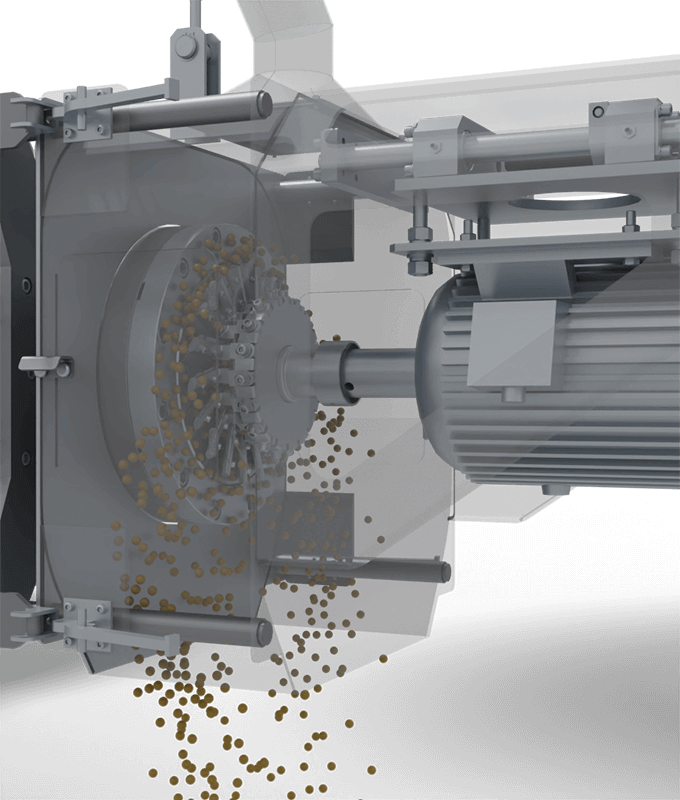

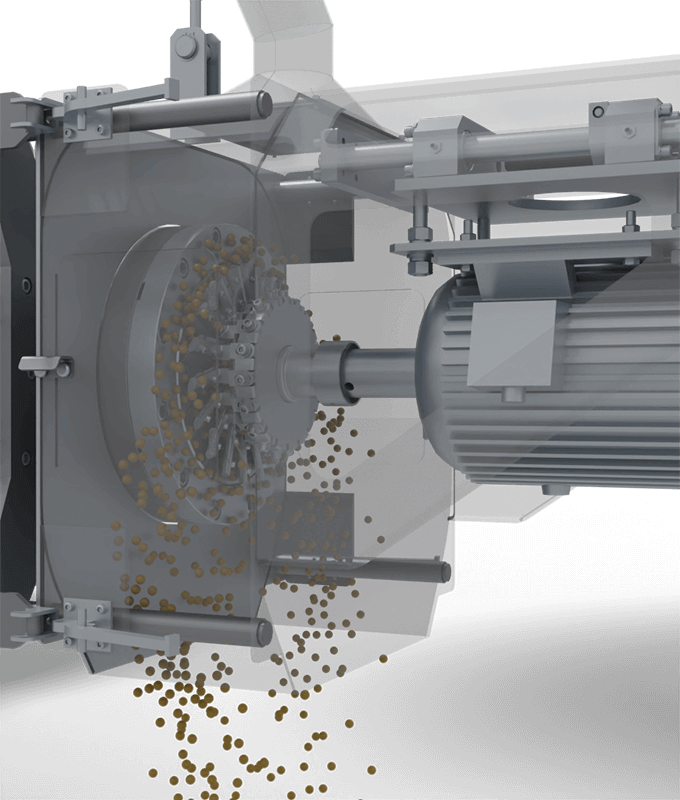

03The extruded pellets are uniform and of good appearance.+Uniform and efficient conditioning technology, screw configuration technology and CFD simulation technology were used to optimize the discharging device and hole distribution on the die plate, further improving the uniformity of extruded pellets, and ensuring the variation of pellet size is ≤0.1.

03The extruded pellets are uniform and of good appearance.+Uniform and efficient conditioning technology, screw configuration technology and CFD simulation technology were used to optimize the discharging device and hole distribution on the die plate, further improving the uniformity of extruded pellets, and ensuring the variation of pellet size is ≤0.1. -

04High degree of automation to ensure uniform product quality+Modular intelligent control, independent monitoring of key parameters, high degree of automation. Equipped with standardized modules, such as system automatic feeding, one-click preheating, one-click conditioning, one-click extruder and auxiliary equipment start, SME online control, one-click shutdown, and one-click extruder flushing, to achieve a high degree of automation and reduce dependence on workers.

04High degree of automation to ensure uniform product quality+Modular intelligent control, independent monitoring of key parameters, high degree of automation. Equipped with standardized modules, such as system automatic feeding, one-click preheating, one-click conditioning, one-click extruder and auxiliary equipment start, SME online control, one-click shutdown, and one-click extruder flushing, to achieve a high degree of automation and reduce dependence on workers.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN