FAMSUN ruminant concentrate supplement solutions, backed by extensive industry experience, focuses on optimizing feed processing to help you significantly reduce energy consumption and raw material costs. We are dedicated to providing high-quality, nutritionally balanced concentrate supplements, comprehensively supporting your production needs, ensuring the healthy growth of cattle and sheep, and escorting your farming endeavours towards success.

Provide Partners with Professional Solutions

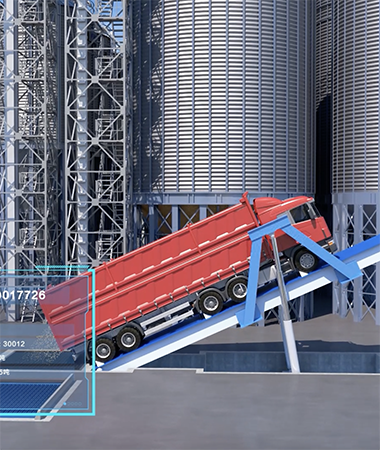

Yuanxing of Youran Dairy Ruminant Feed Project in Daqing

The Yuanxing project in Daqing is a ruminant feed production and processing plant designed and constructed by FAMSUN, with an annual production capacity of 200,000 tons in a single shift. The plant includes two ruminant feed production lines, one for organic ruminant feed and another for calf feed.

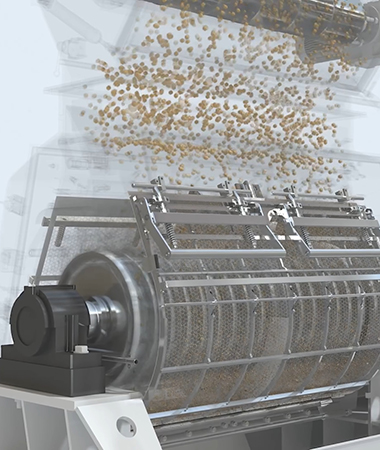

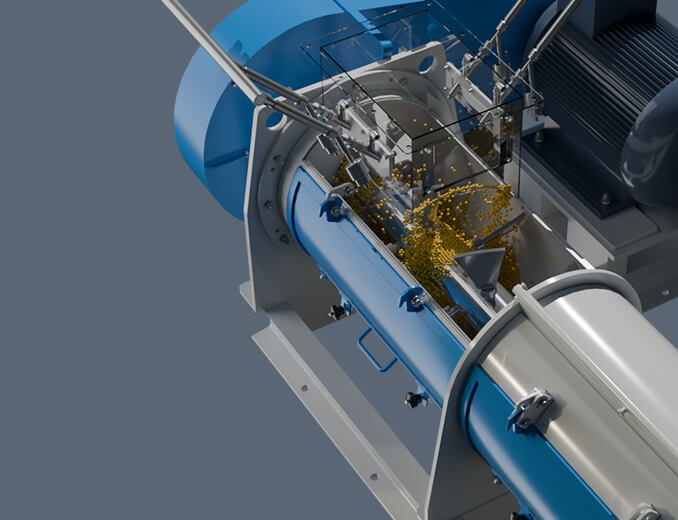

The project features FAMSUN's latest KN2 ruminant-specific pellet mill, calf feed-specific static mixer, molasses mixer, molasses coater, and other specialized equipment for ruminant feed production

It is also equipped with intelligent devices such as FAMSUN’s automatic screen-damage detection system, raw material automatic weighing system, fully automatic packaging scale, and FAMSUN's FimCOS intelligent control system, and it stands as an outstanding representative of intelligent ruminant feed engineering.

Xianchun Ruminant Feed Factory in Huaian

Xianchun ruminant feed project in Huaian integrates one efficient ruminant feed production line, one precision premix line, and an intelligent mechanical palletizing system, with an annual production capacity exceeding 180,000 tons of dairy cow concentrate supplement and 20,000 tons of pelleted calf feed.

The project utilizes internationally leading production processes and intelligent control systems to ensure the excellence and stability of feed quality, accurately blending various additives and trace elements to meet the nutritional needs of ruminant animals throughout their entire life cycle.

Bright Ruminant Feed Project in Huaxian

The Bright project in Huaxian, with an annual production capacity of 150,000 tons of ruminant feed, includes a MUZL600 belt pellet mill with a capacity of 30t/h, where pellet feed accounts for about 10% of the total production.

The batching scales are equipped with an air system to enhance the dosing accuracy and control dust in the workshop. Belt conveyors are utilized for packaging pellet feed, while a dedicated double-screw dosing scale is employed for powder ingredients, improving sealing performance and precision during discharge. A specialized premixed feeder is adopted for the micro ingredient, controlling dust dispersion during feeding. The project's layout is spacious, with wide pathways, including reserved visitor access, cargo elevators, prefabricated bridge and hanger supports, separate bridge trays for power and control lines, and colour-coded cables.

Production Process

Featured Solutions

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN