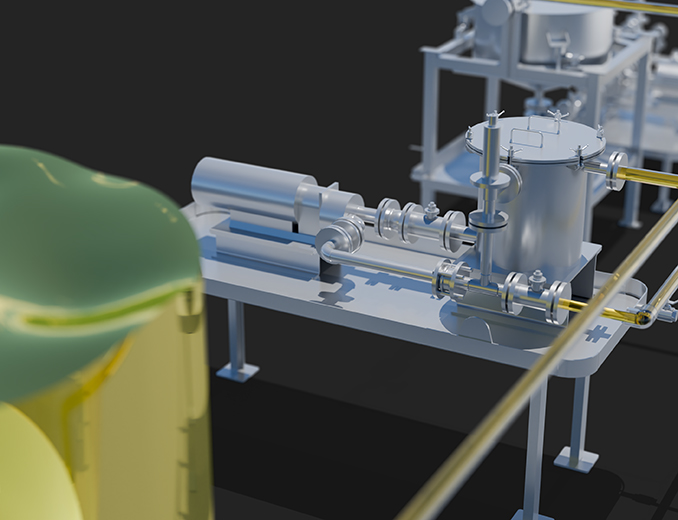

FAMSUN’s premix equipment engineering line is dedicated to the research and development, manufacturing and efficient system solutions for feed additive production equipment, such as factory planning, engineering design, complete sets of equipment, factory construction and integrated control, including production lines of mixed feed additives, enzymes, acidifiers, flavour agents, sweeteners and traditional Chinese medicine additives.

Provide Partners with Professional Solutions

Adisseo Additive Project

Nanjing Adisseo Additive Project: The project is a new large-scale additives factory in Nanjing built by Adisseo (a former French company acquired by Sinochem Group), which marks the first time that FAMSUN cooperates with a major player in the chemical industry to build a large-scale additives production line with an annual output of more than 30,000 tonnes, meeting the stringent standards of the chemical industry. The project encompasses five production lines, constituting a comprehensive additive project integrating sweeteners, flavour agents, vitamins, and hybrid additives.

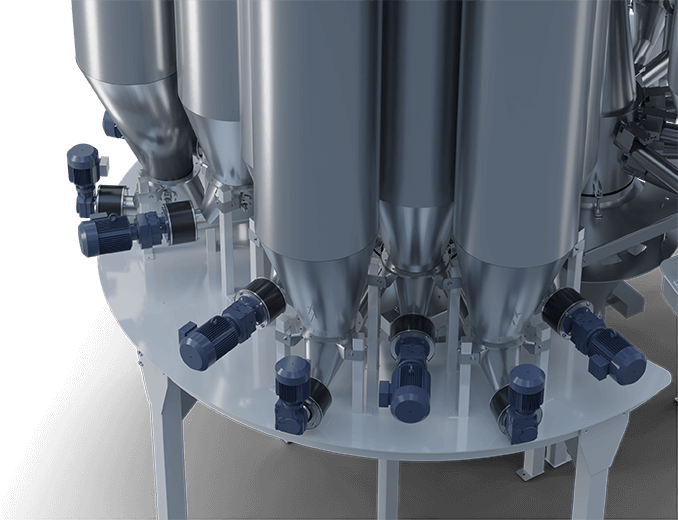

KDN Biotech Enzyme Preparation Engineering in Weifang

FAMSUN holds more than 90% of the market share in Vland Biotech additives projects and has constructed many factories for Vland Biotech Inc. in Qingdao, Linyi, Weifang, and so on. There are four production lines for high-grade enzyme preparation in KDN factory in Weifang. The project realizes full traceability from the raw material end to feed mills and farms through ERP seamless information technology.

Menon Biotech Project in Suzhou

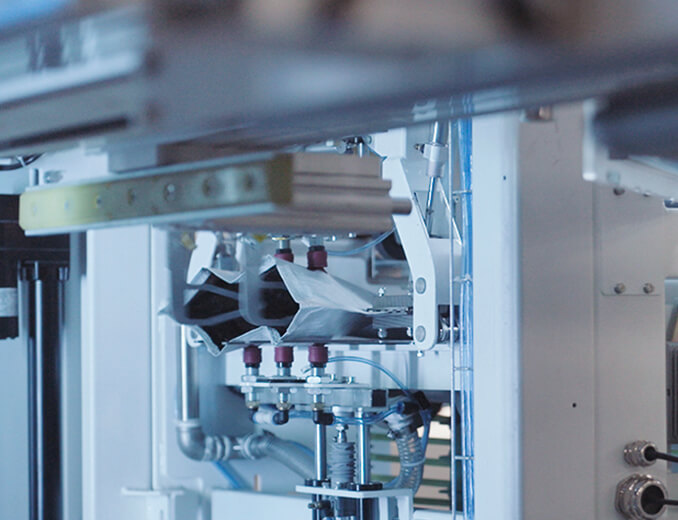

The project is located in Taicang City, Jiangsu Province, covering a total area of about 20,000 square meters with seven independent production lines, which are primarily dedicated to the research, development and large-scale production of acidifiers, flavour agents and sweeteners.

The whole project includes intelligent warehouses, automatic labelling stations, automatic packaging lines and an intelligent control center.

Production Process

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN