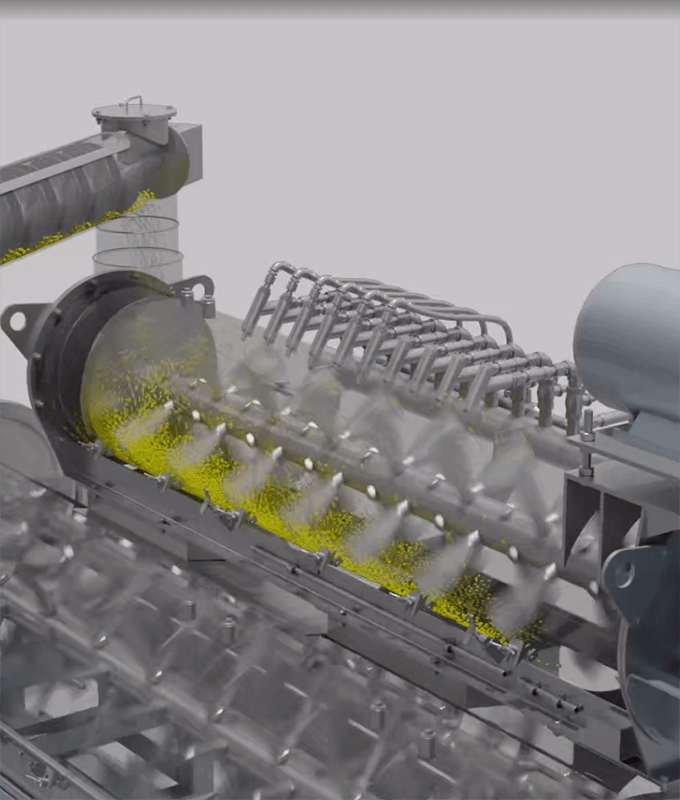

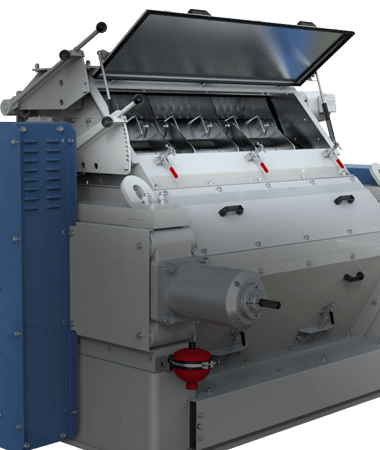

FAMSUN corn and oat flaking solutions, with a wealth of industry experience, specialize in ruminant feed processing, helping you significantly reduce energy consumption and raw material costs. We are committed to providing high-quality, nutritionally balanced corn and oat flakes, fully supporting your production needs, ensuring the healthy growth of ruminants, and safeguarding your cattle farming business.

Production Process

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN