High-end System Solutions for Compound Premix Feed Production Line

Provide Partners with Professional Solutions

Egdoo Premix Project in Liaoning

The Egdoo Intelligent Factory in Liaoning is located in Tieling City, the granary in northern Liaoning Province, and mainly produces high-end compound premix. It can achieve a total output of 100,000 tonnes per year, which is a model project of intelligent premix production constructed by FAMSUN. Based on the FimCOS Intelligent System developed by FAMSUN, the factory realizes the data and visualization of the whole process from raw materials to finished products, ensuring the safety and traceability of the products. The unique feeding technology eliminates mismatches, the high-precision automatic batching system achieves nutritional accuracy, and intelligent equipment management maintains product quality. At present, the project has become a new benchmark for premix engineering on the land of Liaoning area.

CP Premix Project in Liuzhou

CP Premix (Tianjin) Co., Ltd. invested in a new high-grade premix plant in Liuzhou, Guangxi province, with a product range of premium premixes for pigs, poultry and ruminants. FAMSUN delivered the EPC project. With barcode identification technology, based on WEM4000's full traceability system of the production process, it realized the efficient, safe and collaborative production of multiple types of finished products. Each year, 60,000 tonnes of high-grade premix is provided for local use.

INVE Premix Project in Qingyuan & Liyang

FAMSUN holds a market share of over 65% in the TRS Group premix projects and has constructed multiple best mix and premix factories for the TRS Group. Examples include the INVE 80,000-ton-per-year premix project in Qingyuan and the INVE 60,000-ton-per-year premix project in Liyang. Through ERP seamless information technology, these projects have realized full traceability from the raw material end to the farming end.

Twins Premix Project in Chongqing

Twins Premix Project in Chongqing.

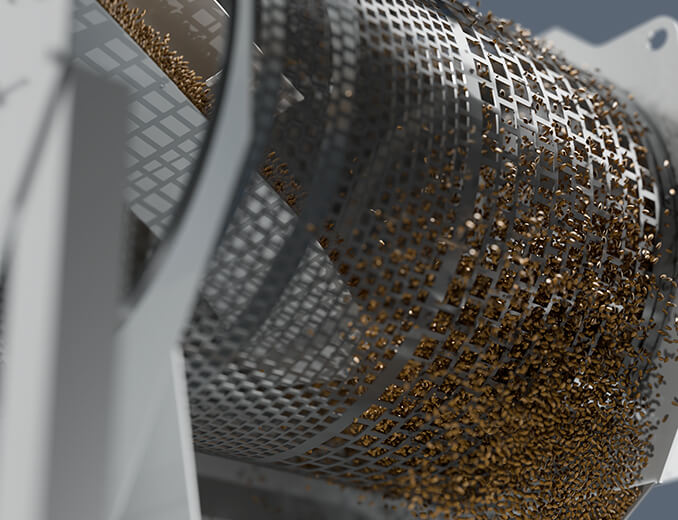

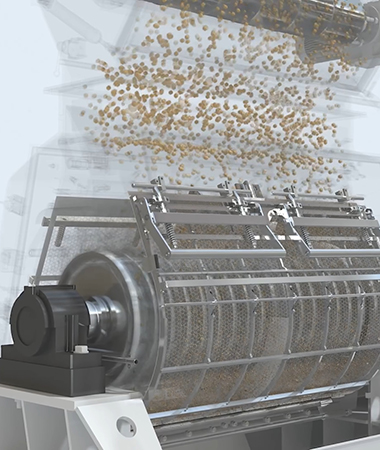

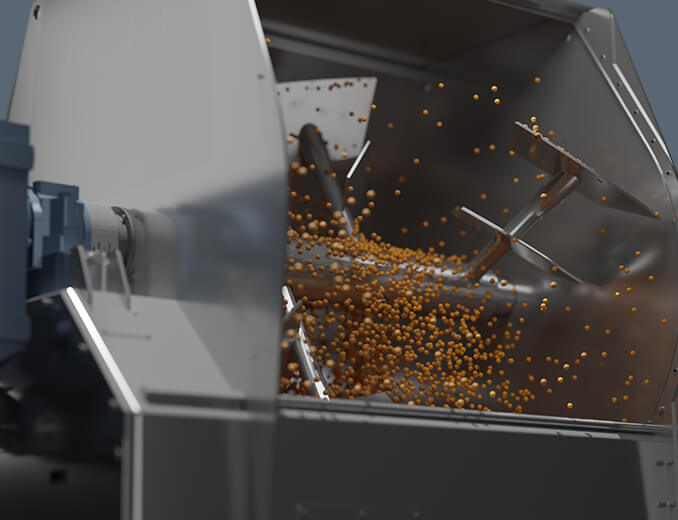

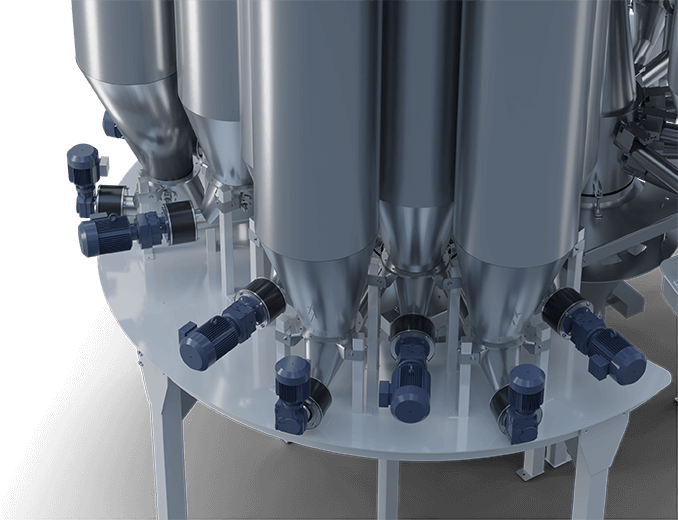

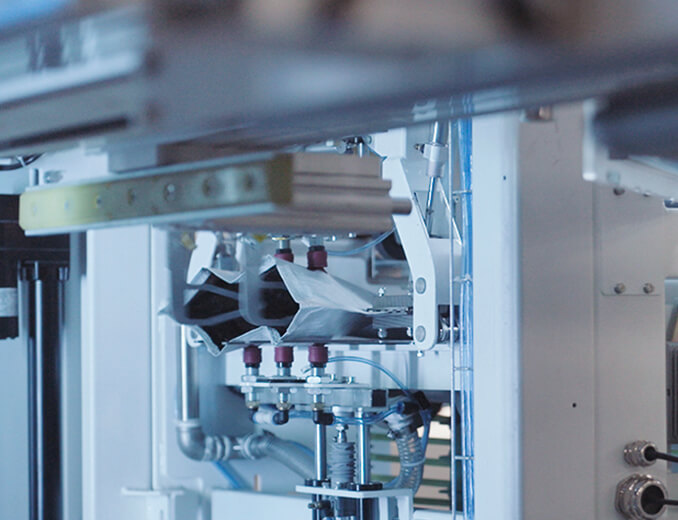

Production Process

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN