Pneumatic conveying is a specific application of fluidization technology, used to transport granular or powdery materials along the direction of airflow in an enclosed pipeline by means of aerodynamic energy. It offers strong flexibility, zero pollution, continuous production, a high level of automation, and easy maintenance. This technology is widely applied in industries such as chemicals, food, mining, and energy.

For example, pneumatic conveying requires minimal space and allows for flexible pipeline layouts, enabling easy navigation through complex terrains and confined spaces, making it highly suitable for mining or renovation projects with challenging landscapes. Additionally, it is clean and hygienic with excellent airtightness, preventing secondary pollution and moisture-induced material degradation, which is particularly advantageous in the food and chemical industries.

In conclusion, pneumatic conveying not only enhances conveying efficiency and reduces investment costs but also effectively addresses material contamination and loss issues during transportation, making it an ideal solution for modern industrial production.

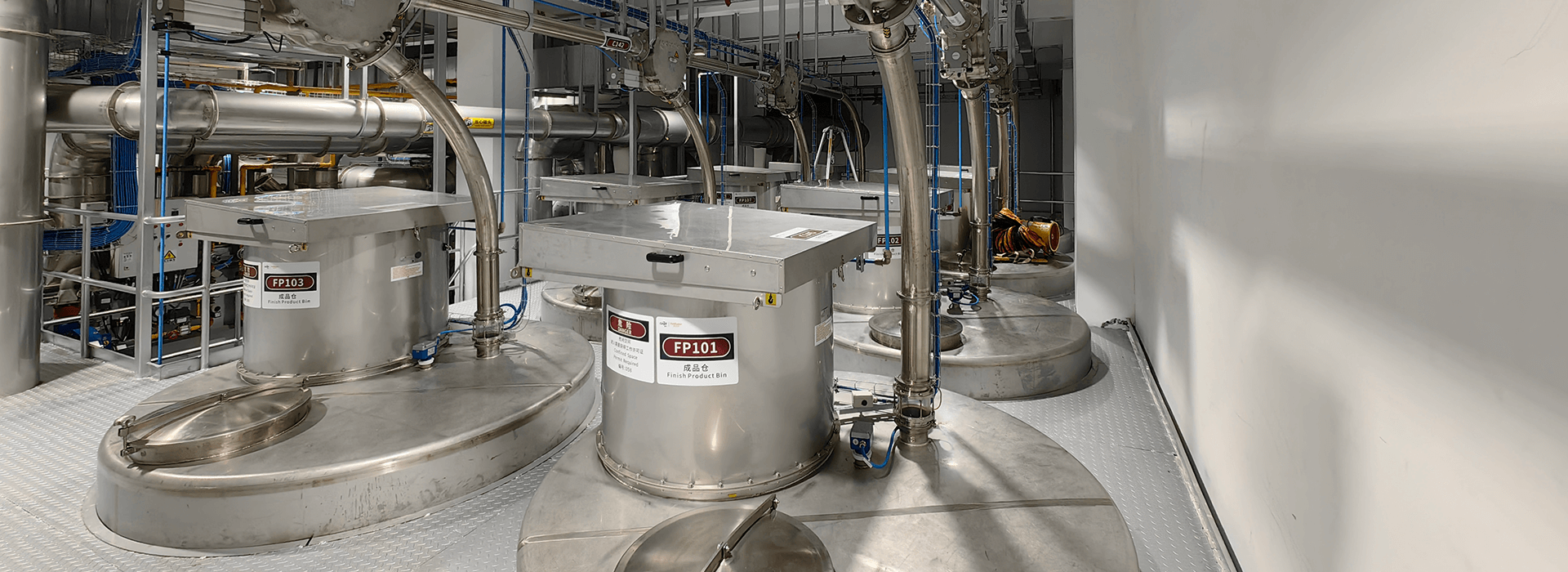

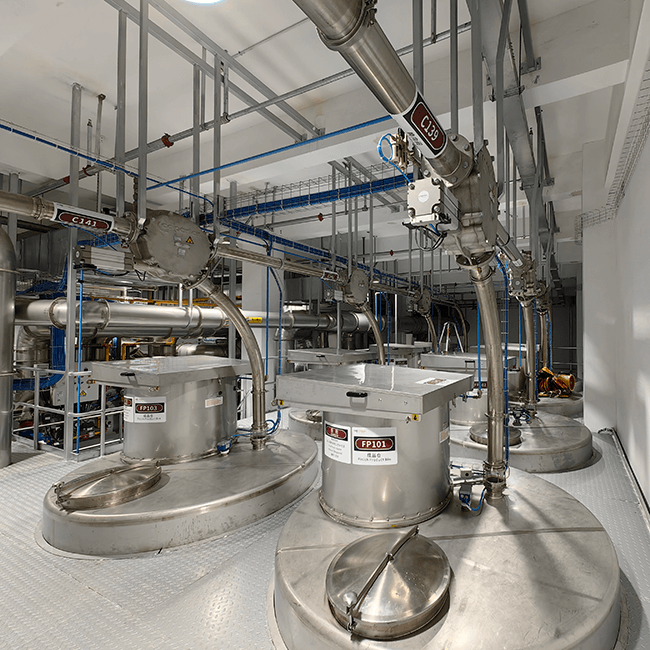

Blow Tank/Vessel Dense Phase Pneumatic Conveying System

- Widely used in industries such as pharmaceuticals, chemicals, new energy, food, metallurgy, and premix production, it is particularly suitable for powder conveying. Its conveying performance is especially notable for powders that are prone to moisture absorption, highly abrasive, or susceptible to segregation.

More

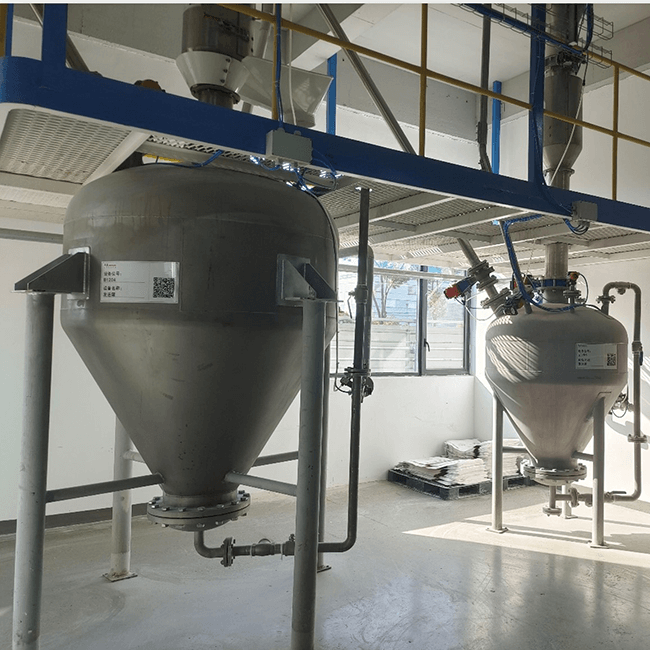

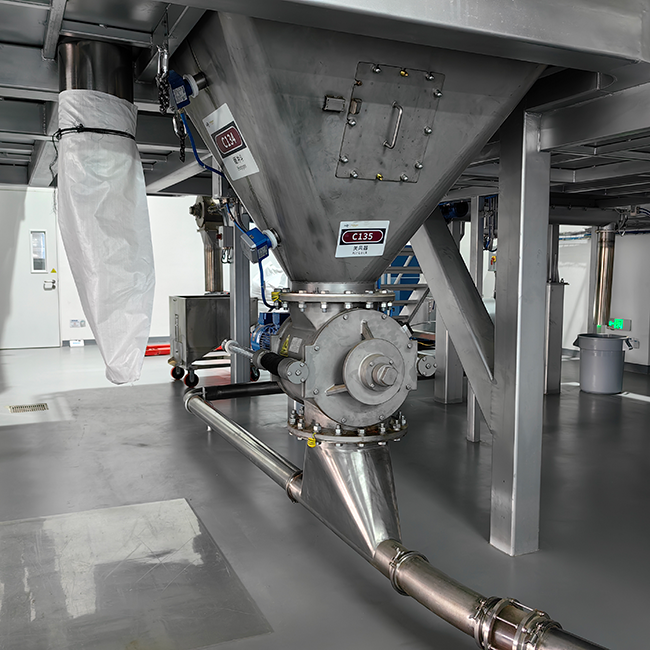

Pressure Dense Phase Continuous Pneumatic Conveying

- Benefiting from its lower conveying speed and continuous conveying characteristics, this type of pneumatic conveying is more suitable for continuously produced, fragile granular materials or those that require low-speed transportation (such as particles coated with powder on the surface).

More

Vacuum Dilute Pneumatic Conveying

- Suitable for transporting materials with strict requirements on leakage due to contamination or toxicity, as well as situations where it is inconvenient to install blowers or vessels at feeding points.

More

Pressure Dilute Phase Pneumatic Conveying

- Pressure dilute phase pneumatic conveying is suitable for materials that are not concerned with breaking or segregation during transport, such as single-component powders, powders that are not concerned with segregation, and granular materials that are hard and not easily broken. Applicable for sending materials from one point to multiple points.

More

Application

Multiple Industries

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN