Conveying equipment contains multiple categories of products, including chain conveyors, bucket elevators, screw conveyors, and slide gate. In the grain and oil processing industry, conveying equipment connects various process sections into a whole, efficiently and stably transporting raw materials, semi-finished products, and finished products between various stages to ensure the smooth progress of the production process. The design of the equipment aims to improve production efficiency, reduce labor intensity, and ensure the quality and safety of feed. Through reasonable process layout and equipment selection, the efficiency and quality of feed production can be significantly improved. This can be applied to the feed, grain and oil, and flour industries.

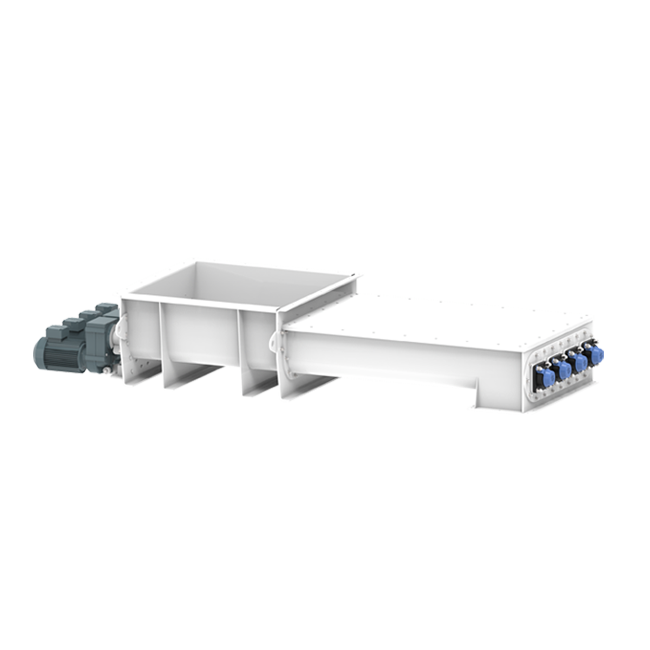

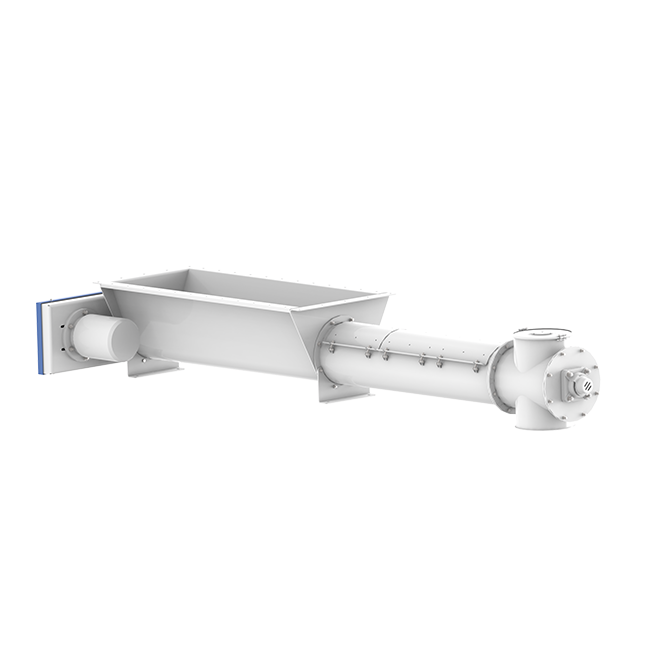

LSUW Multi-Row Screw Conveyor

- The LSUW multi-row screw conveyor is specifically designed for soybean meal silo systems. It is suitable for conveying meal materials such as soybean meal and can effectively mitigate the issue of material arching inside the silo. However, it is not suitable for conveying granular materials like corn and wheat.

More

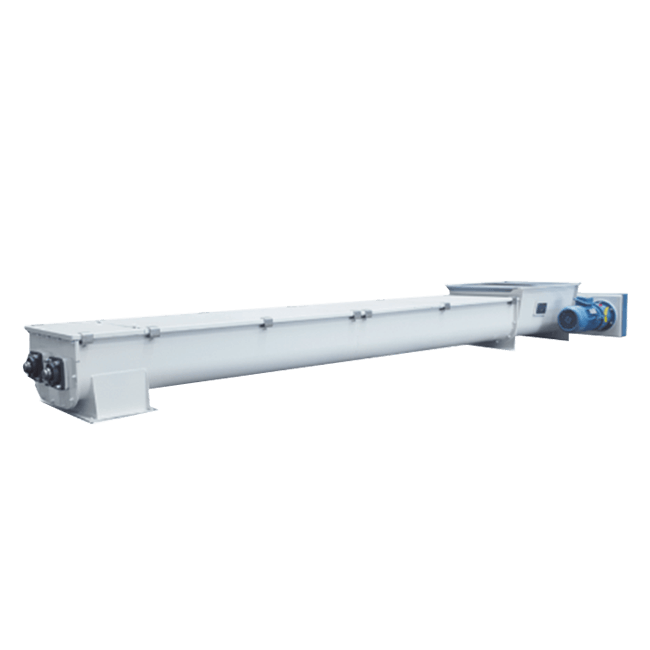

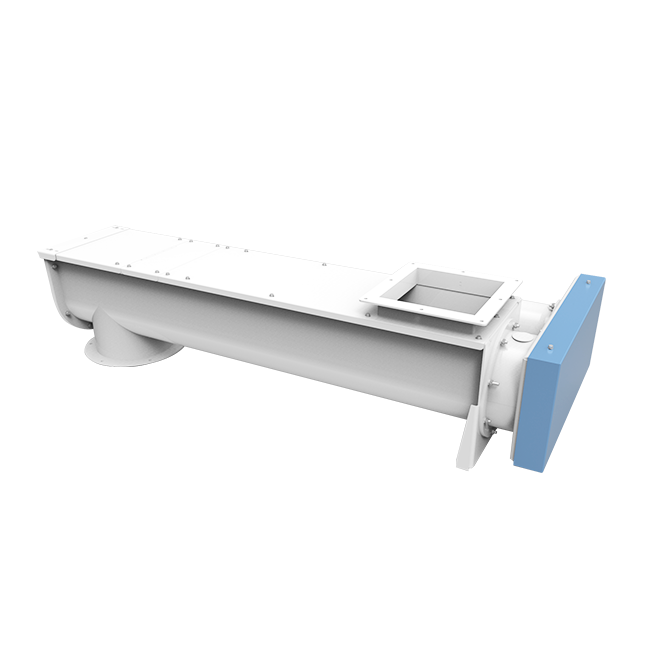

LSUW/LSGW Screw Conveyor

- The screw conveyors are utilized under the silo to efficiently and accurately discharge a variety of materials. They are widely applicable in the feed industry for conveying powdered and granular materials. Based on user requirements, differentiated configurations and personalized customization can be implemented to achieve high-quality production.

More

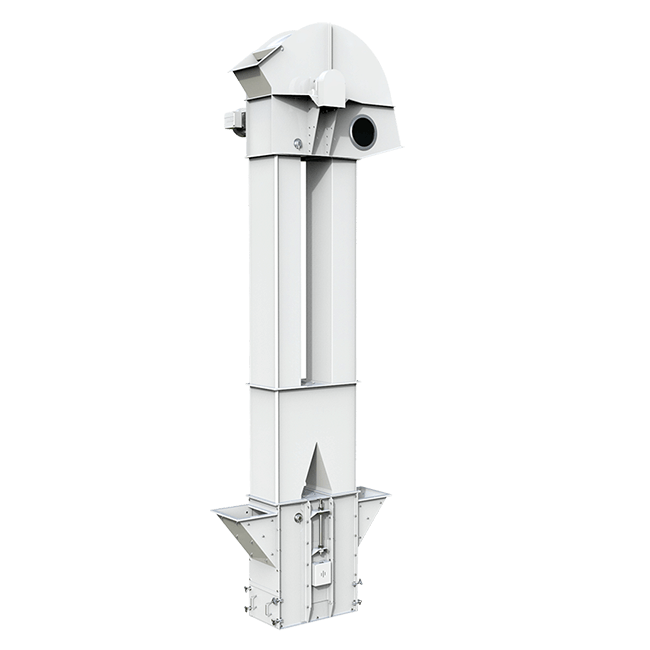

T-Series Elevator

- The T-Series offers a comprehensive range of specifications and models, featuring various rotational speed configurations to accommodate different types of materials.

More

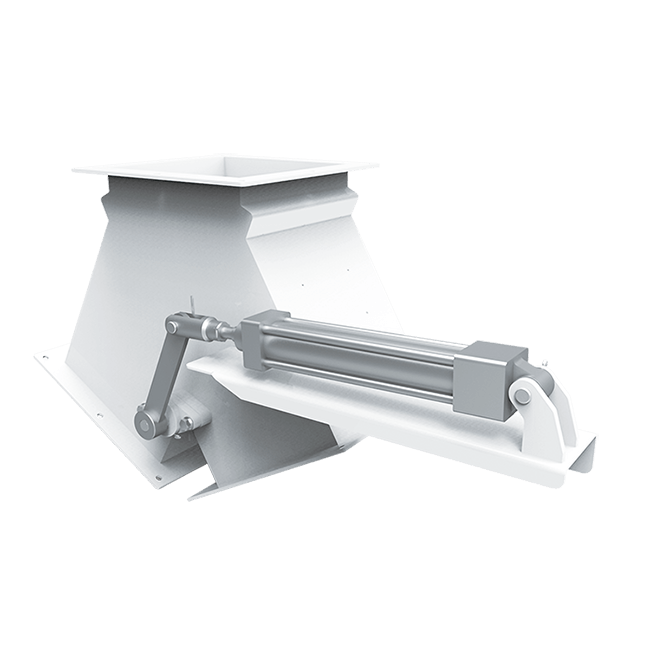

The BDQY/BDQC/TBDQ/TBDD series of Three-Way Distributors

- Three-way distributors are widely used for material diversion. They are classified into flap and diverting hopper structures, which can respectively accommodate different material conditions.

More

LSGF Material-Sealed Screw Conveyor

- The material-sealed screw conveyors are designed for use in grinding systems and installed underneath the grinder. As a specialized equipment for hammer mills, it creates a stable negative pressure within the grinder's chamber to block air circulation and convey materials simultaneously.

More

LSUS Screw Conveyor

- The Screw Conveyor is designed for horizontal material conveying (with a conveying angle ≤20°). It features simple installation and convenient layout. With a small inlet, it allows for multiple feed inlets and outlets, providing flexible arrangement options. However, during the process layout, it should be noted that the material flow entering the screw conveyor should be stable and controllable. It is widely applicable in the feed industry for conveying powdered and granular materials. Based on user requirements, differentiated configurations and personalized customization can be made to achieve high-quality production.

More

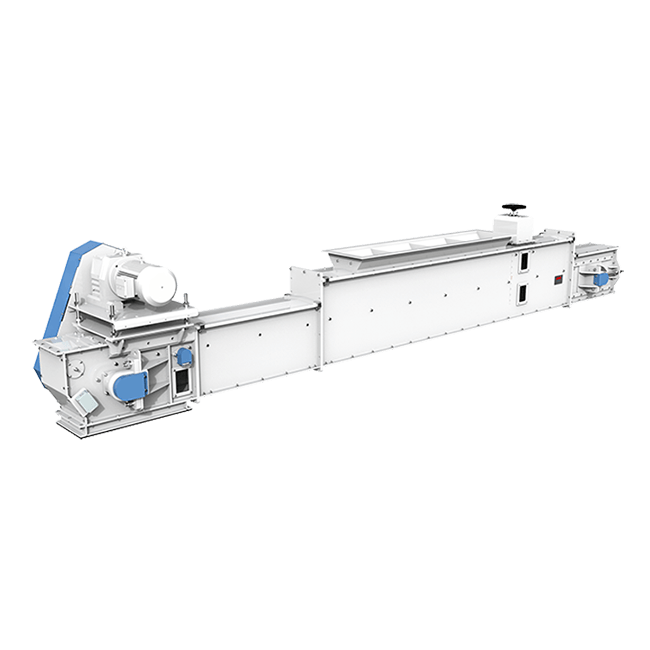

TGSP Chain Conveyor

- TGSP chain conveyor is primarily used for conveying dry, powdered, or granular materials in the feed industry, but is not suitable for transporting brittle granular materials requiring low breakage rates. It features a simple structure, small size, excellent sealing performance, and and is relatively convenient for installation and maintenance. It allows for multi-point feeding and discharging, offering flexible process selection and layout.

More

VZMQ Series V Gate Valve

- This series of gate valves is suitable for both powder and granular materials, enabling simultaneous discharge from both sides.

More

ZMQP/ZMDP Series Self-Cleaning Gate Valves

- This series of gate valves are used for self-cleaning discharge with chain conveyors.

More

TZMQ/TZMD/TZMS Gate Valves

- This series of gate valves is widely used in various situations for cutting off material flow from bins and hoppers.

More

Applications

Essential Equipment for All Sections

Featured Solutions

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN