FAMSUN aqua feed solution is oriented toward creating customer value. Aiming at every pain point and demand of customers, FAMSUN focuses on comprehensively improving the efficiency of operation and maintenance, supporting the high-quality, sustainable development of customers, and creating development opportunities through the fitting of innovative products with intelligent and digital application technology.

Provide Partners with Professional Solutions

Tiancheng Intelligent Plant in Nantong

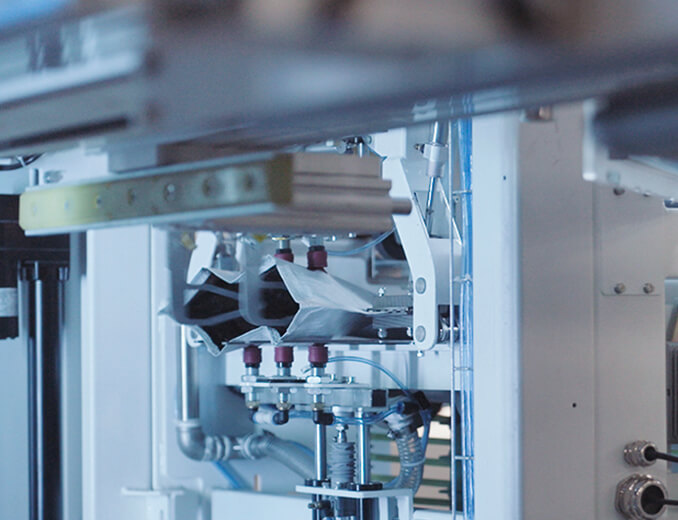

The project is one of the comprehensive intelligent feed mills with the highest intelligence standards in China. The production lines comprise the premix line, pig and poultry feed line, shrimp and crab feed line, extruded aquafeed, and raw material expansion line. It’s designed with an annual yield of 600,000 tons of high-grade feed. The factory adopts FAMSUN's intelligent one-card management system, intelligent production equipment, and control system, as well as a fully automated packaging and palletizing system. For intelligent management, it employs the MES system independently developed by FAMSUN, ensuring fair and transparent production performance assessment, maintaining order on the production site, and enabling full control of operations remotely from the control room.

Deepak Aquafeed Project in India

FAMSUN builds the Deepak aquafeed project in India. The project covers extruded floating feed and pelleted shrimp feed. The three workshops are all designed by FAMSUN. Workshop one has a high-grade extruded fish feed line; Workshop two has one high-grade extruded fish line and three pelleted shrimp feed lines. Workshop three has two extruded fish lines and four pelleted shrimp lines. It is one of the largest comprehensive aquafeed mills in India and has a high level of intelligence.

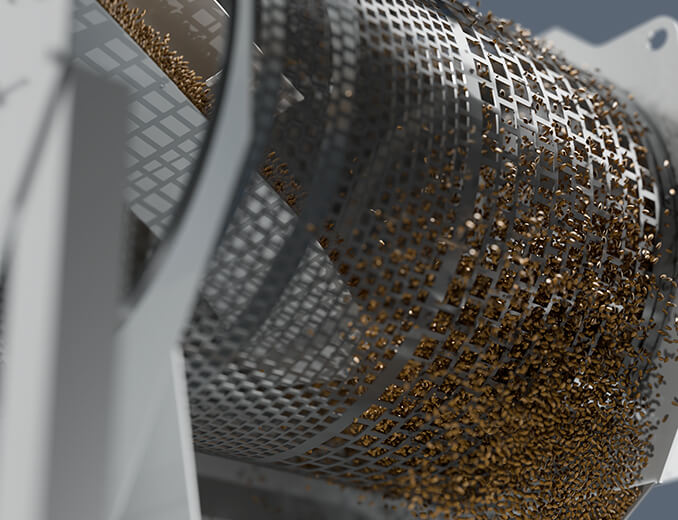

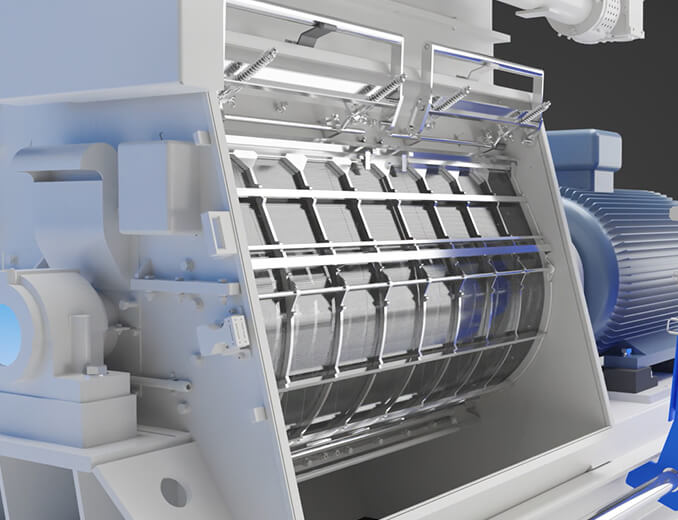

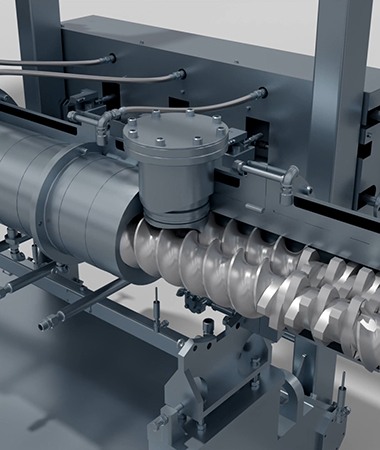

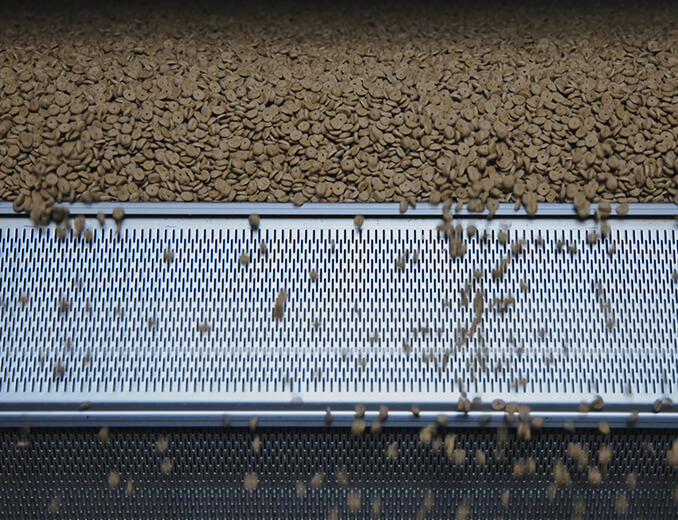

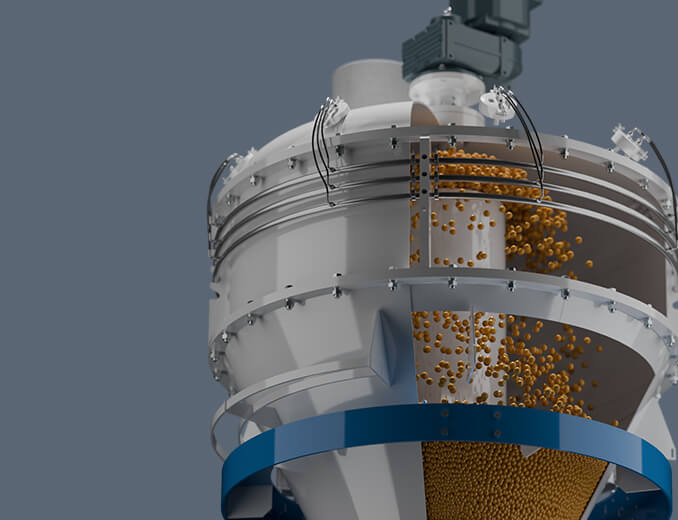

Production Process

Featured Solutions

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN