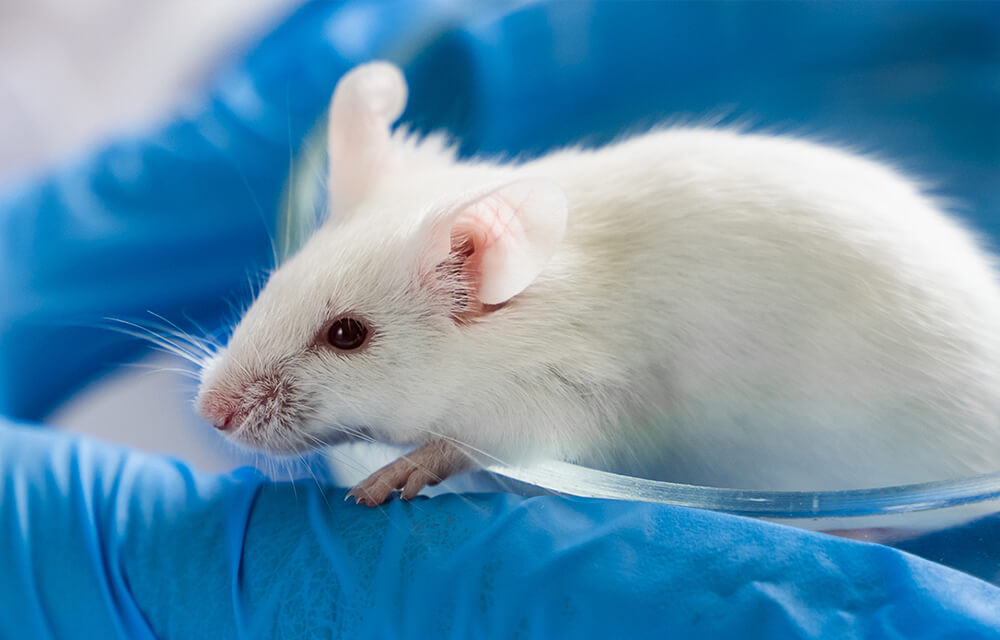

With rich experience in the industry, FAMSUN's pelleted shrimp feed solution focuses on optimizing the processing technology. Through research on shrimp's physiological properties, nutritional characteristics, raw materials, and finished product control requirements, FAMSUN proves safe, reliable, efficient, and energy-saving pelleted shrimp feed solutions.

Provide Partners with Professional Solutions

Tiancheng Intelligent Plant in Nantong

This project is one of the most advanced comprehensive intelligent feed mills in China. The complete production line covers premix, pig and poultry feed, shrimp and crab feed, extruded aquafeed, and raw material expansion lines, with an annual output capacity of 600,000 tons of high-grade feed. In terms of intelligent production, the factory adopts FAMSUN's intelligent one-card management system, intelligent production equipment and control system, as well as a fully automated packaging and palletizing system. FAMSUN also developped its MES system for intelligent factory management, ensuring fair and transparent production performance assessment, established operation protocal on site and enabling full control of operations remotely from the control room.

Haid Aquafeed Project in Ecuador

FAMSUN supplies the machines for the Haida project in Ecuador. There are four 1200-ton silos, three 2500-ton horizontal warehouses, and three 150-ton bins for bulk material. In the single workshop with the largest capacity in the region, there are six pelleting lines and two extrusion lines. The pelleting lines are equipped with six 1200h belt pellet mills (220kW) and the latest automation control system in the industry. The three-step grinding system improves grinding efficiency and reduces particles to a smaller size. The plants use a centralized dust collection system to reduce dust emissions and prevent air pollution. The automation control system uses MyCos 2, developed by FAMSUN, to optimize production scheduling based on orders and improve the timely rate of production delivery.

Haid Aquafeed Project in Vinh Long, Vietnam

The Haid shrimp feed line is located in Longhu County, Vinh Long Province, in the south of Vietnam. It is the third feed mill FAMSUN built for Haid in the Vietnam area. The project is split into three phases. There are two shrimp feed lines and 10 bins for bulk meals in the first phase, one extruded fish feed line in phase two, and two shrimp feed lines and ten bins for bulk meals in phase three. The Haid shrimp feed business is booming in Vietnam and Southeast Asia, where the market demand for shrimp feed is huge, and the supply has been in shortage. The successful production of the plant is of important strategic significance for the development of the shrimp feed market and the promotion of Haid's market share.

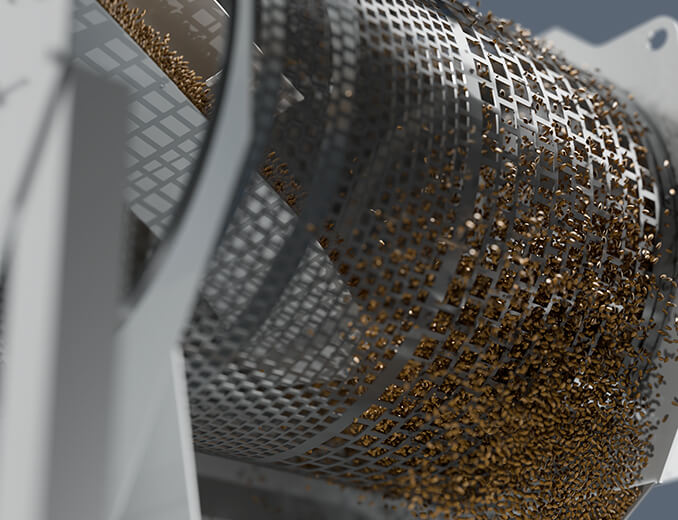

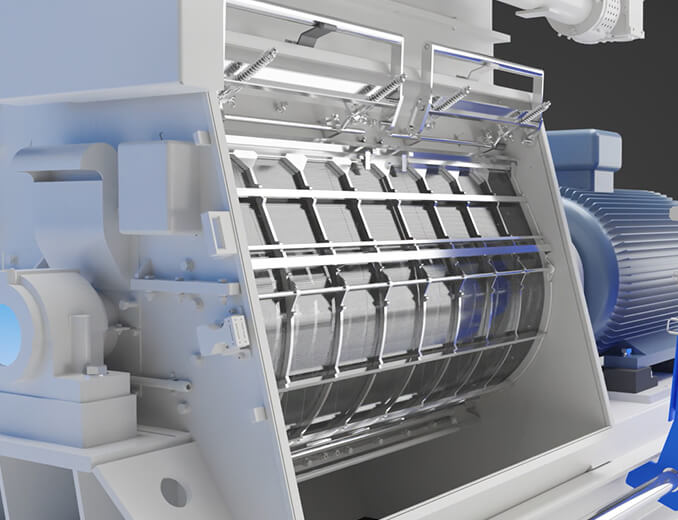

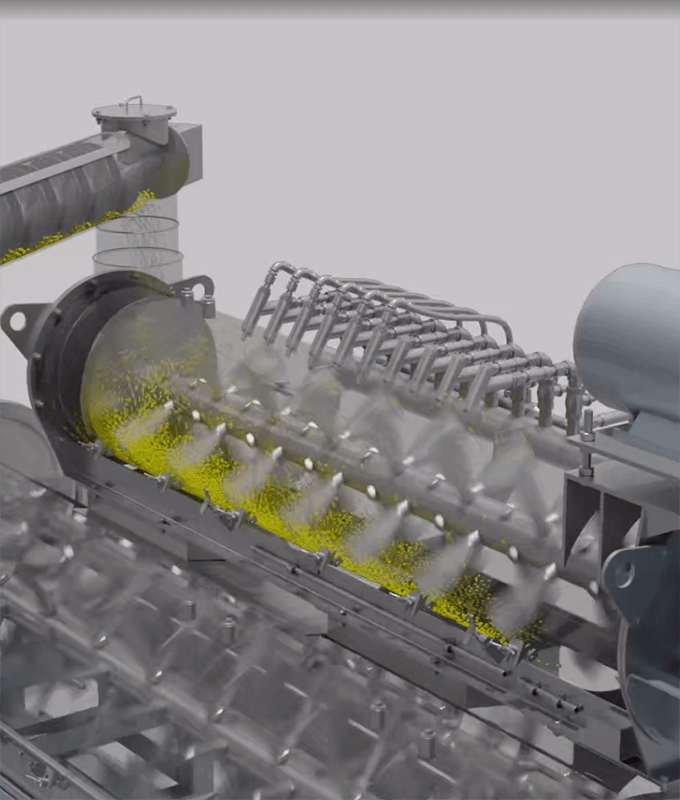

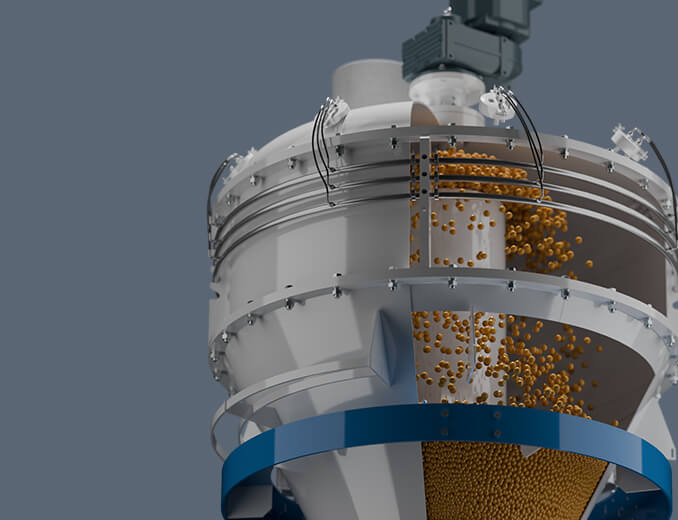

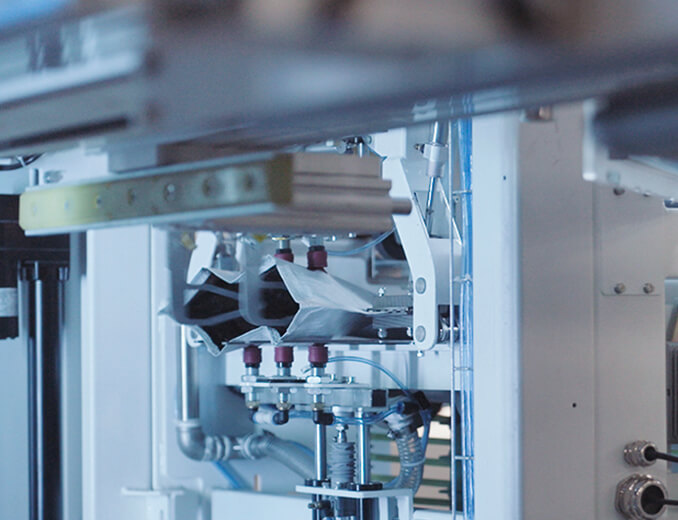

Production Process

Featured Solutions

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN