High-quality broilers come from high-quality feed. FAMSUN’s broiler feed solutions are built on years of accumulated technological expertise and can be customized according to different farming methods. We provide high-quality feed for various growth stages of broilers, improving feed conversion ratios and helping you achieve the goal of quality improvement and efficiency enhancement.

Provide Partners with Professional Solutions

Dachan Food poultry feed project in Bengbu (annual yield: 600,000 tons)

The DaChan Food plant in Bengbu, built by FAMSUN, is one of the most intelligent and largest modern feed mills in the Yangtze River Delta region. With an annual design capacity of 600,000 Tonnes, the project has ten 2500-ton silos for corn and five 20-ton pelleting lines, four 3ton/batch mixing lines, and a 6000m³ finished product bin. The project is equipped with a FAMSUN intelligent solution, focusing on "vertical storage, bulk handling, automatic production, intelligent control, fresh product, and information-based management," to support Dachan Food to enhance its core competitiveness and achieve sustainable development. The whole process is automated and precise, and the production efficiency of key processes has been increased by more than 30%, which effectively ensures product quality and food safety.

Xiang Jia pig and poultry feed project (annual yield: 1 million tons)

The 1-million-ton high-end pig and poultry feed smart factory built by FAMSUN for Xiang Jia covers an area of 146,700 square meters. Phase I of the project includes five pelleting lines and one extrusion line. The entire facility is designed with a focus on green environmental protection and biosecurity, featuring separate clean and contaminated zones to prevent cross-contamination. By adopting advanced intelligent feed processing equipment and an information-based management system, the plant ensures biosecurity at the source, eliminating the risk of disease transmission through feed production.

The facility also includes a premix feed workshop equipped with the WEM intelligent system for complete traceability. Using a unique code for each product, the system allows precise tracking of information. All equipment is integrated into the FimCOS system, enabling digital management of the entire process—from smart formulation management and efficient raw material cleaning to high-quality feed production, automated packaging, and bulk distribution. A real-time dashboard provides complete visibility and control over the entire operation, from raw material intake to product dispatch.

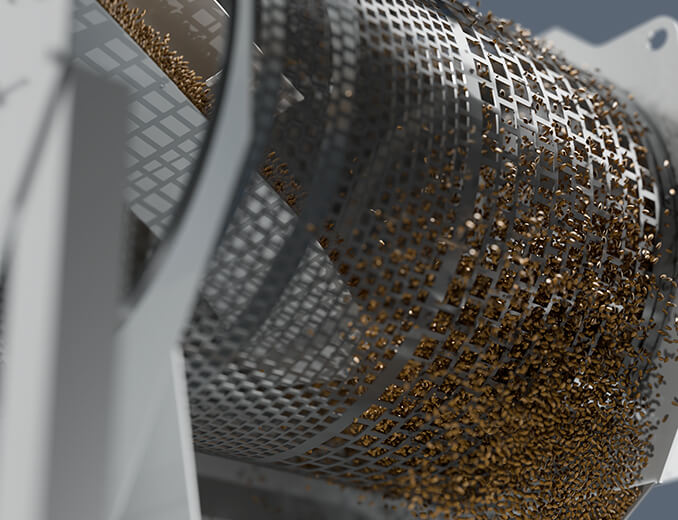

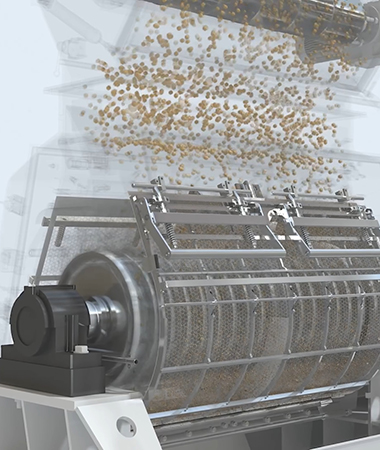

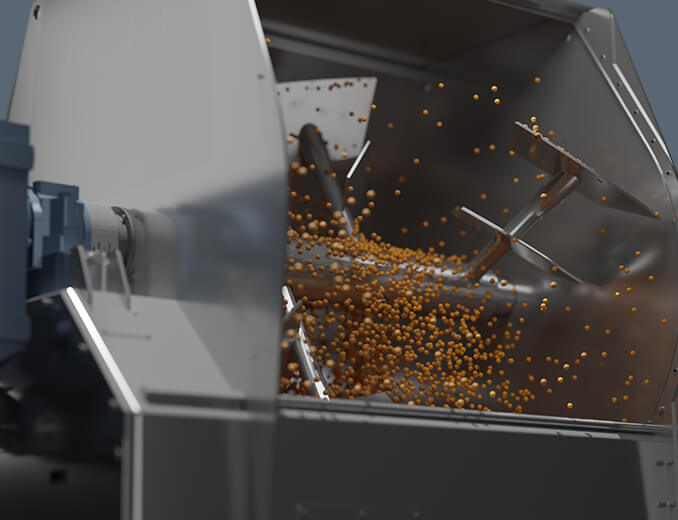

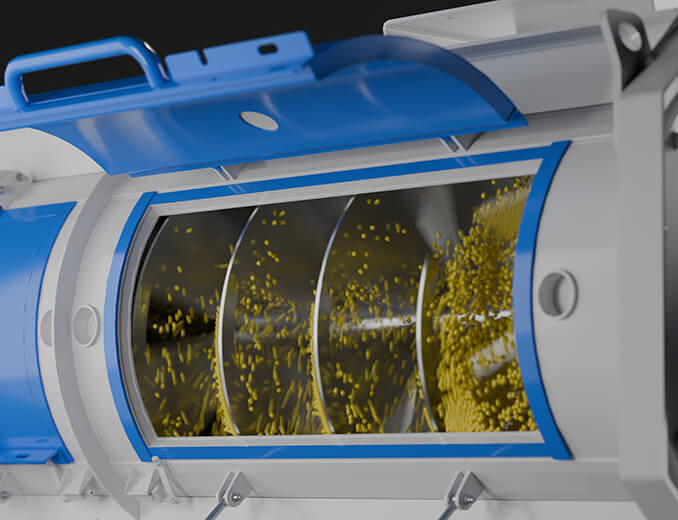

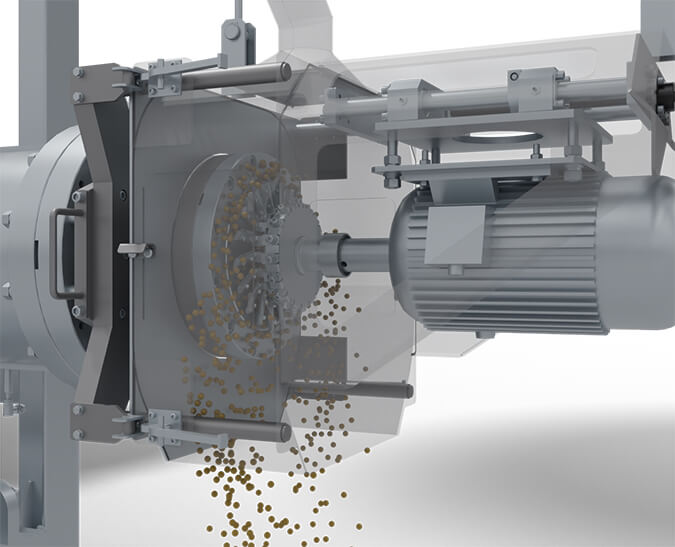

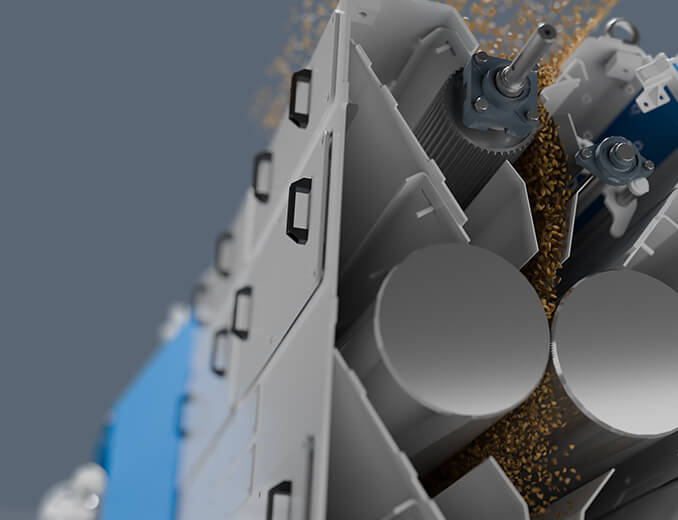

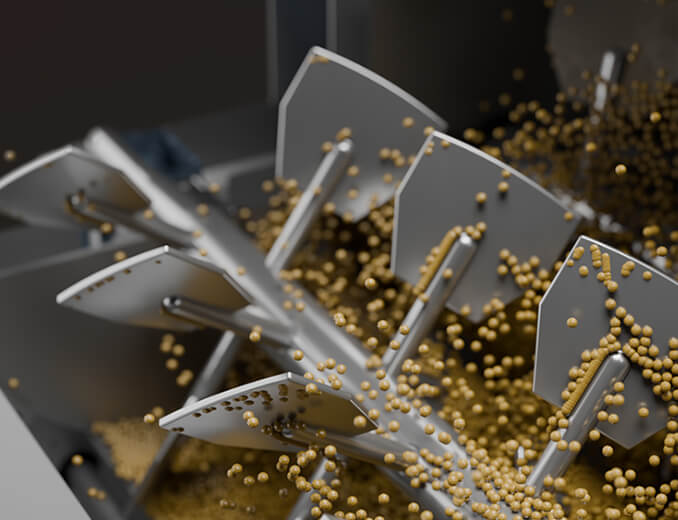

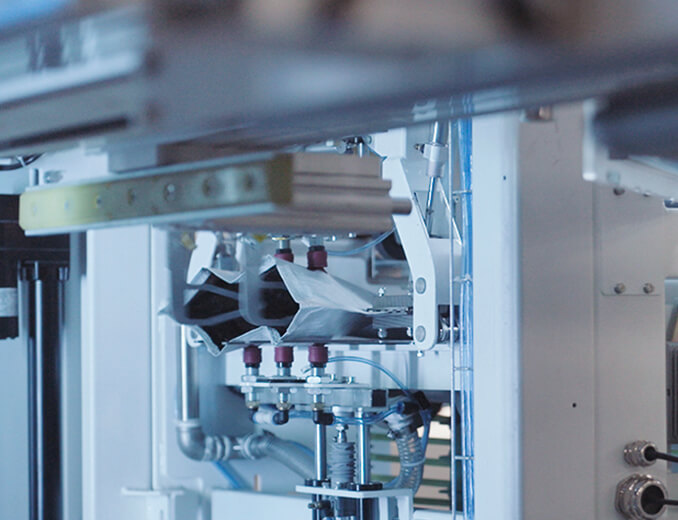

Production Process

Featured Solutions

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN