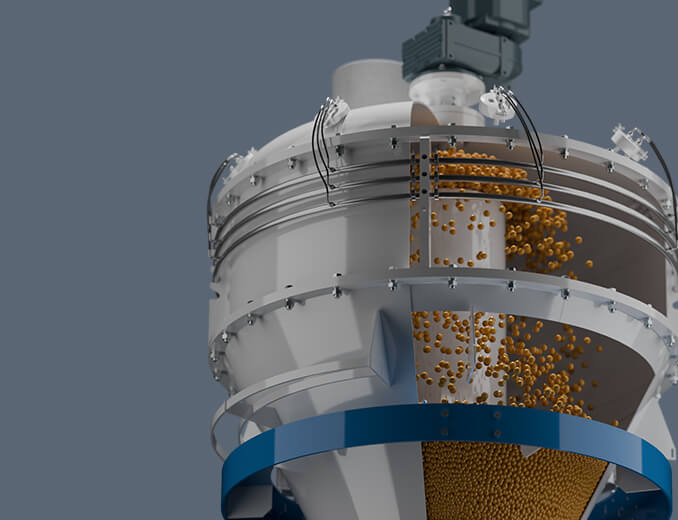

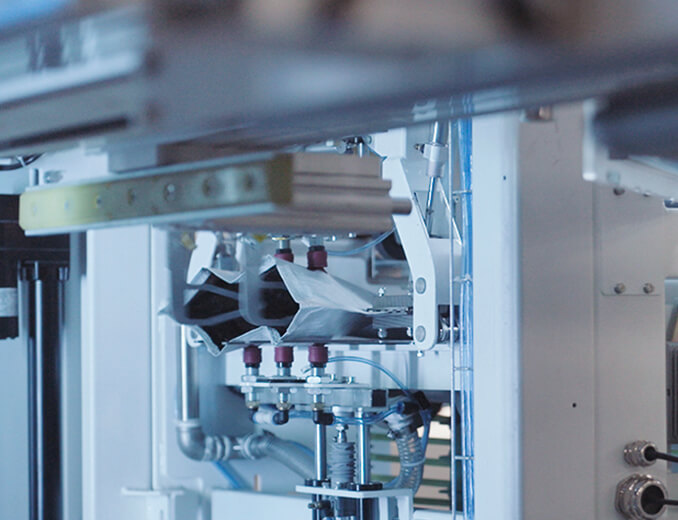

FAMSUN's extruded aqua feed solutions integrate both floating and sinking feed production technologies. We precisely address customer painpoints by core technologies of intelligent digital solutions.By combining cutting-edge processing techniques with smart equipment systems, we enable comprehensive operational efficiency improvements while ensuring premium feed nutrition quality, driving high-quality development in aquaculture.

Provide Partners with Professional Solutions

Tiancheng intelligent plant in Nantong

This project is one of the most advanced comprehensive intelligent feed mills in China. The complete production line covers premix, pig and poultry feed, shrimp and crab feed, extruded aquafeed, and raw material expansion lines, with an annual output capacity of 600,000 tons of high-grade feed. In terms of intelligent production, the factory adopts FAMSUN's intelligent one-card management system, intelligent production equipment and control system, as well as a fully automated packaging and palletizing system. FAMSUN also developped its MES system for intelligent factory management, ensuring fair and transparent production performance assessment, established operation protocal on site and enabling full control of operations remotely from the control room.

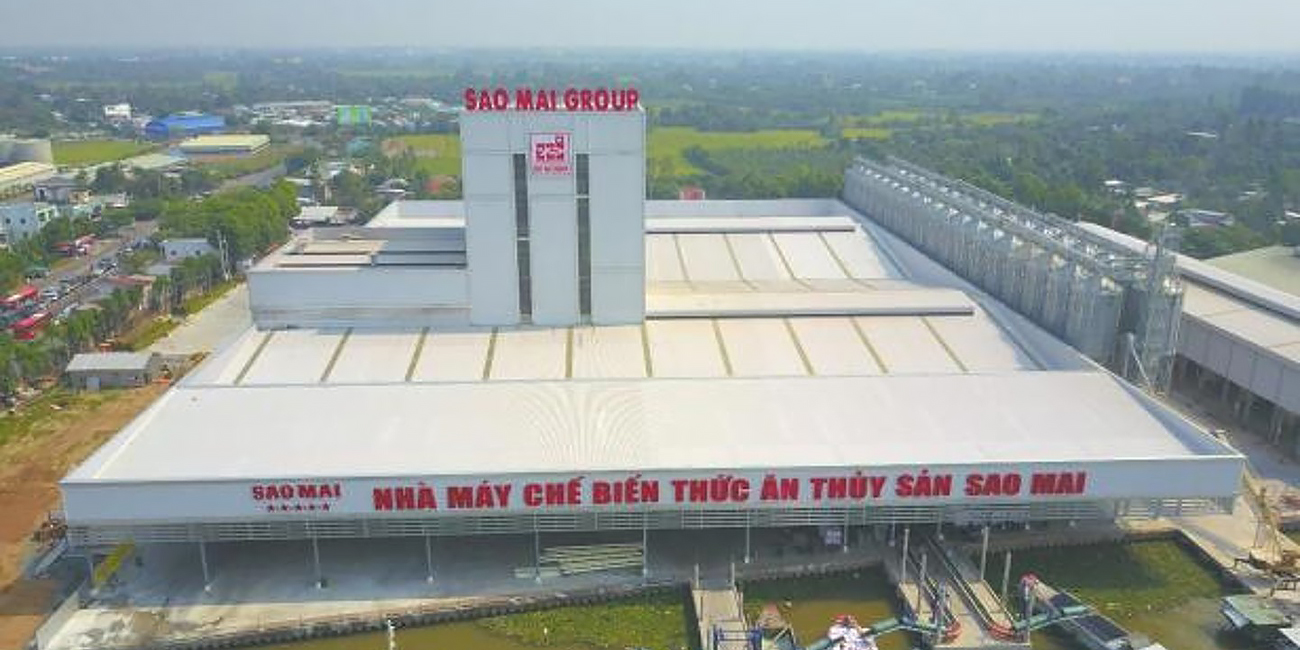

Saomai high-grade aquafeed project in Vietnam

FAMSUN constructs the Saomai high-grade aqua project in Vietnam. The feed mill comprises thirty-six 300-ton silos, two floating feed lines of 12 t/h, one floating feed line of 20 t/h, one shrimp feed of 3 t/h, and the steel structure of the building. It’s designed with an annual yield of 190,000 tons of high-grade aquafeed. FAMSUN's latest grinders, extruders, and dryers, together with the most advanced automation control systems, are used in the factory to ensure the stable and orderly operation of the field. Meanwhile, reducing labor force also helped our customer to cut operational costs.

Haid Aquafeed Project in Ecuador

This project is the Haid Group’s first shrimp feed investment in the Americas. It features a complete set of FAMSUN extrusion and pelleting shrimp feed production lines. Despite the severe challenges posed by the COVID-19 pandemic during installation, FAMSUN's team remained steadfast and successfully completed the commissioning, significantly reducing the overall project timeline. FAMSUN’s pellet mills, extruders, and processes have earned an excellent reputation within Haid Group and the American market, further enhancing our market share for shrimp feed equipment in the region. Today, this project stands as a premier reference site for customers in Ecuador and across the Americas.

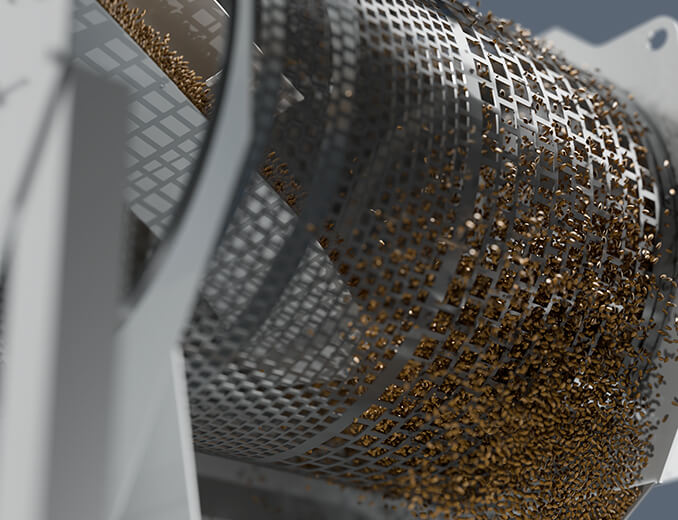

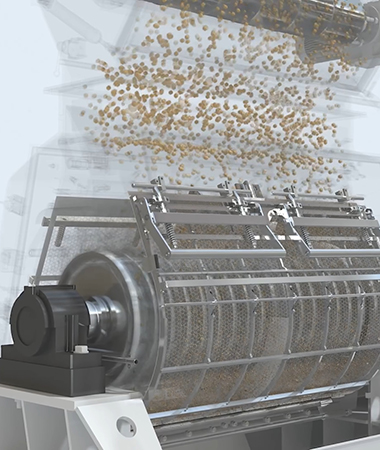

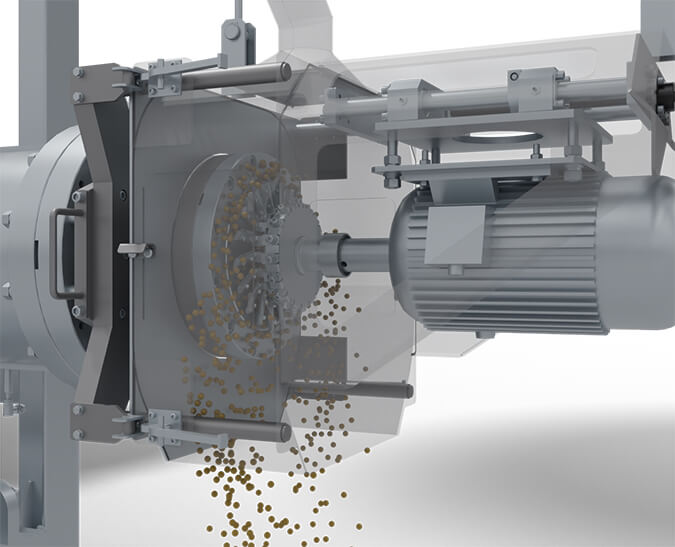

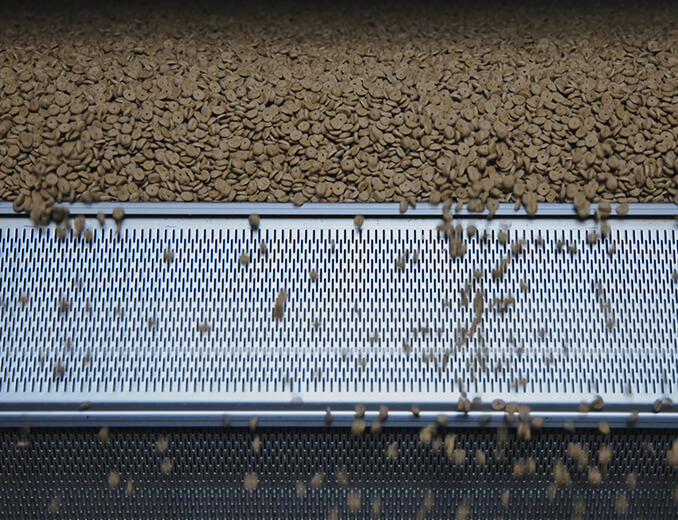

Production Process

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN