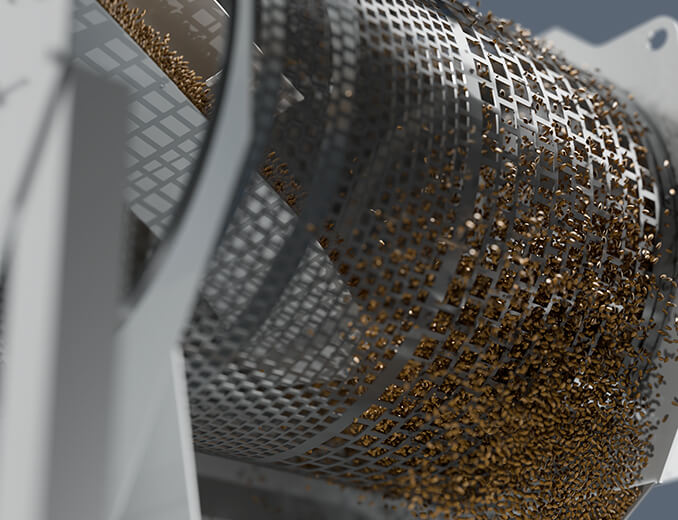

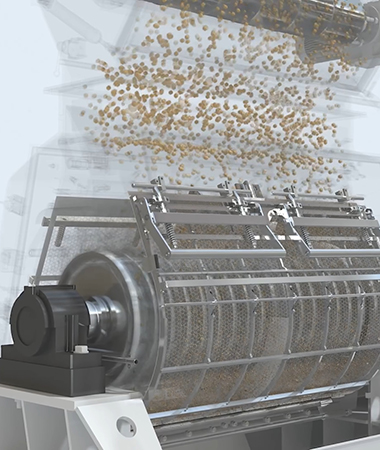

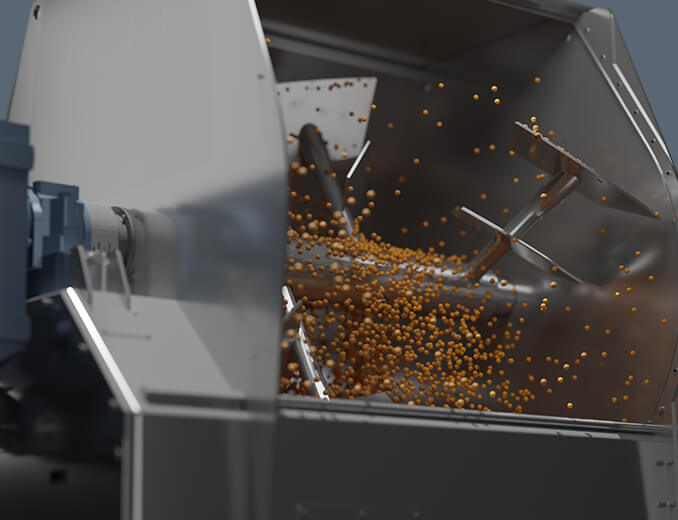

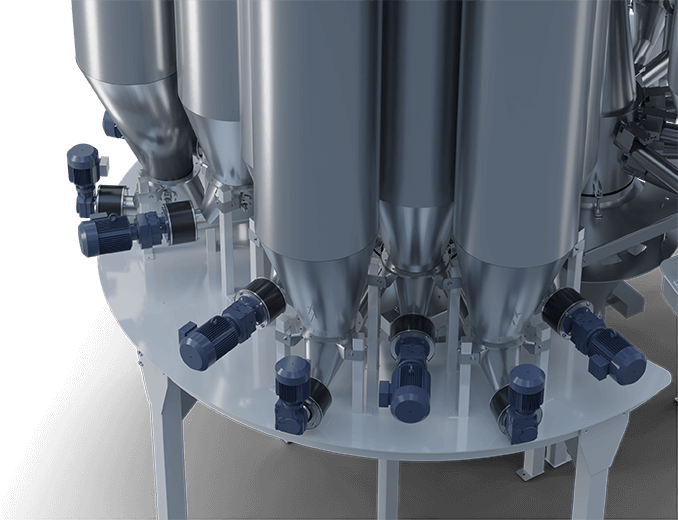

Mineral premix is a mineral additives premix formulated with natural minerals and industrially synthesized single compounds as well as multiple mineral compounds mixed with carriers. The FAMSUN premix equipment engineering line is committed to the research and development and manufacturing of mineral premix production equipment and premix factory planning, engineering design, complete sets of equipment, factory construction and integrated control, and other efficient system solutions.

Provide Partners with Professional Solutions

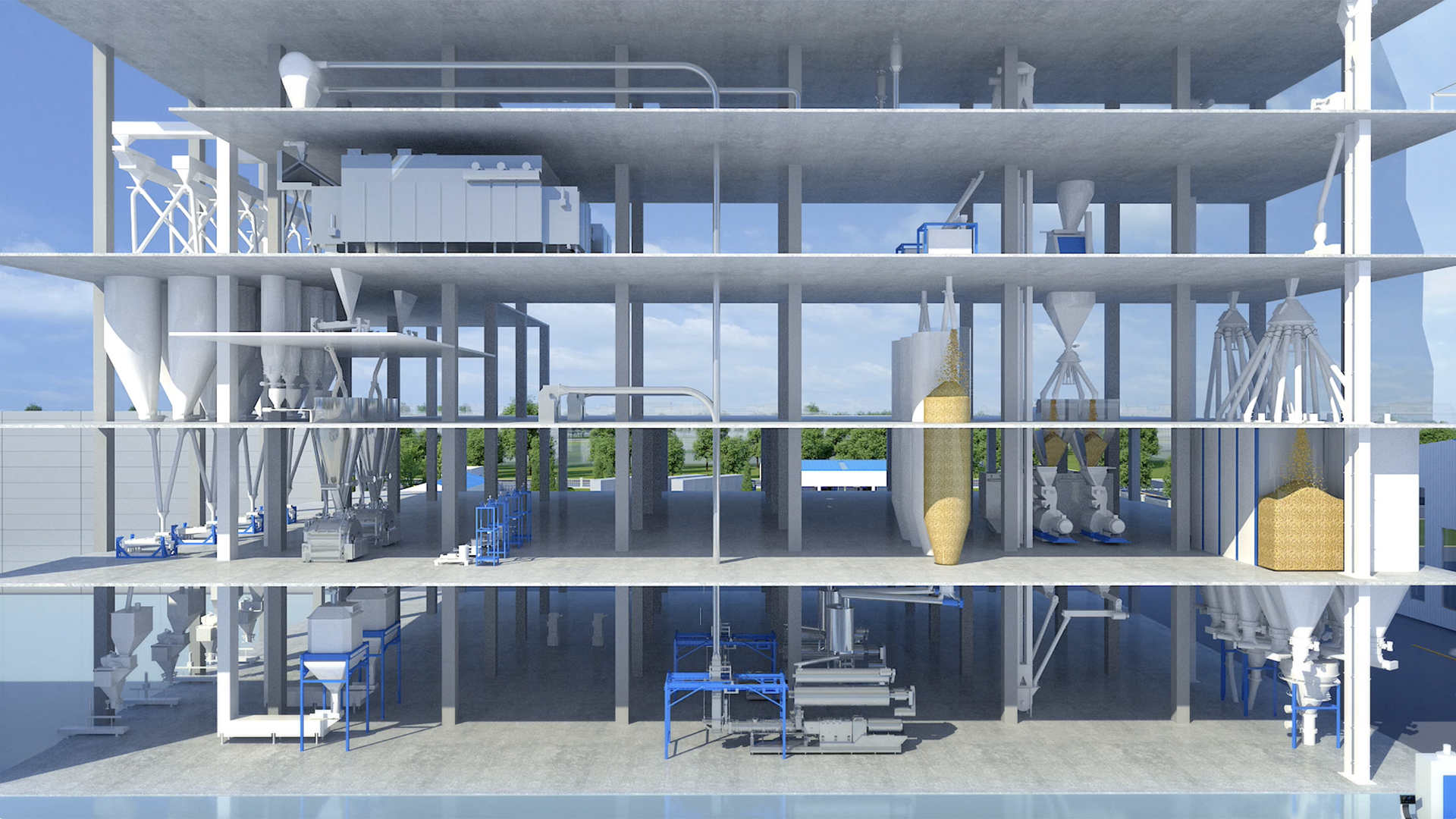

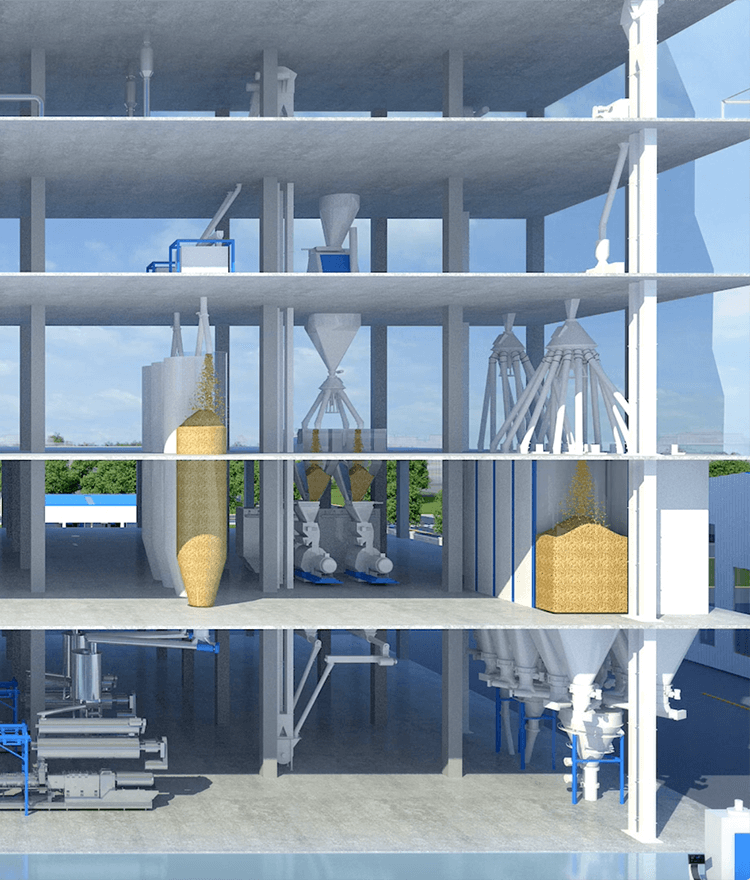

Production Process

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN