With industry leading pathogen inactivation technology and a comprehensive biosecurity system, we ensure healthy pig growth while helping you effectively reduce energy consumption and production costs, supporting the international strategic goal of digitalization and smart transformation in the pig industry.

Provide Partners with Professional Solutions

Haid "Green and Smart IoT" Pig Feed Project in Guizhou

The Haid 180,000-Ton Annual High-Grade Pig Feed Intelligent Project covers various feed types, including sow gestation feed, piglet pre-starter feed, and complete pig feed. FAMSUN, adhering to the "Green and Smart" concept, designed the project with automated equipment such as extruders and pelletizers, automated operations, unmanned gatekeeping, and weighbridge systems. This is Haid Group's first "Green Smart IoT" livestock and poultry project.

Wens Pig Feed Project in Anhui (Annual Yield: 360,000 Tonnes)

The project is composed of intelligent machines, FAMSUN FimCOS control system, FAMSUN MES system, and ERP system. These systems are carefully integrated from bottom to top, incorporating multiple intelligent configurations. The workshop has four pelleting lines and one extrusion line with transparent and efficient management in the factory. Based on the sales order, raw material inventory, production process, and other information from Wen's Group, production order plans are automatically generated. It can quickly respond to the needs of farmers and pig farms, accurately promise the delivery date. Additionally, it can also actively respond to production reschedules due to emergent orders, order change, and other issues, and improve the timely delivery rate. Meanwhile, through complex calculations and overall scheduling, it ensures the timely availability and efficient allocation of resources, including labor, equipment, and materials. The intelligent feed production system can maintain a production capacity of 100 Tonnes per hour, requiring only 16 workers.

Muyuan Complex for Pig Feed in Ruzhou (Annual Yield: 1 Million Tonnes)

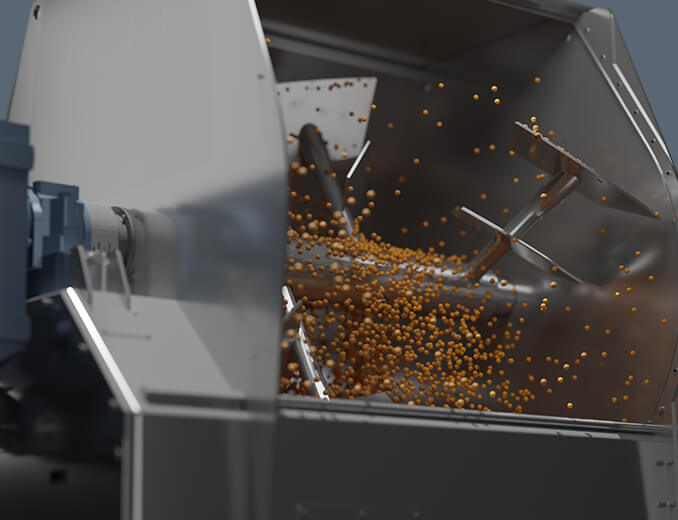

The project includes six 300-ton soybean meal silos, six 1,500-ton grain silos, and four 15,000-ton grain silos. Additionally, outside the main workshop, there are twenty-eight bins for main and minor materials and twenty-three bins for premixes, ensuring fully automated raw material conveying into the workshop.

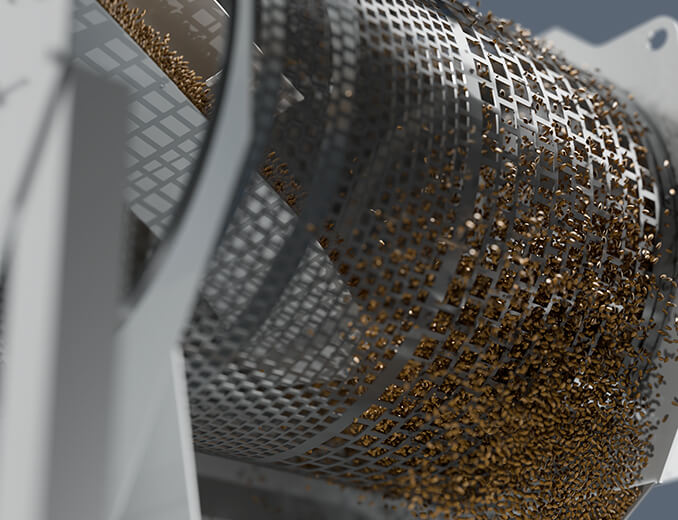

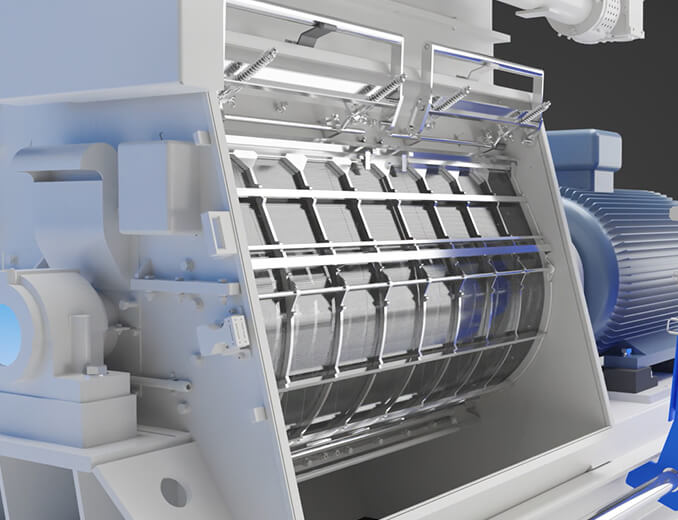

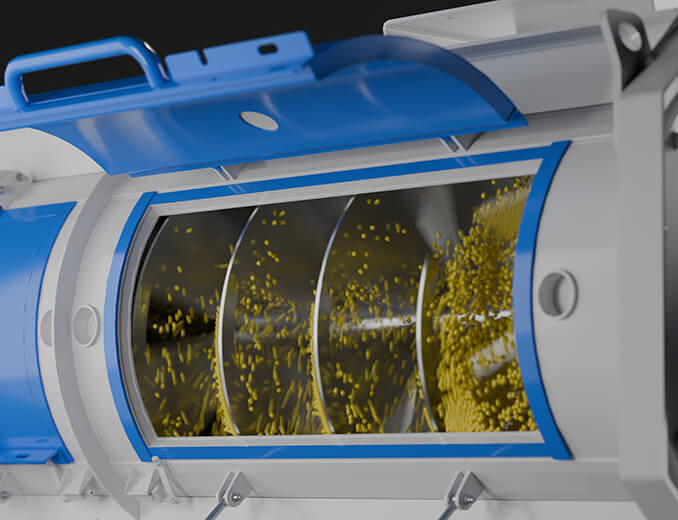

The grinding system is equipped with 315 kW hammer mills, specially designed for Muyuan, which reduces auxiliary facility investment. The conditioning system is configured strictly according to the 3-minute retention time at 85°C requirement, with a layout of one single-shaft conditioner, two thermal conditioners, and another single-shaft conditioner to ensure complete sterilization of each feed particle.

The pelletizing system consists of five 30 t/h pellet mills and two 20 t/h pellet mills. There are no finished product bins; instead, the tubular drag conveyor directly transports the finished pellets to the product tanks, achieving fully automated and unattended finished product conveying.

In line with epidemic prevention requirements, the workshop is divided into dirty areas, clean areas, and ultra-clean areas, completely preventing the spread of African Swine Fever (ASF). Moreover, the workshop adopts a differentiated design to reduce building height, lower civil construction costs, and shorten the overall construction period.

Production Process

Featured Solutions

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN