Performance Characteristics

-

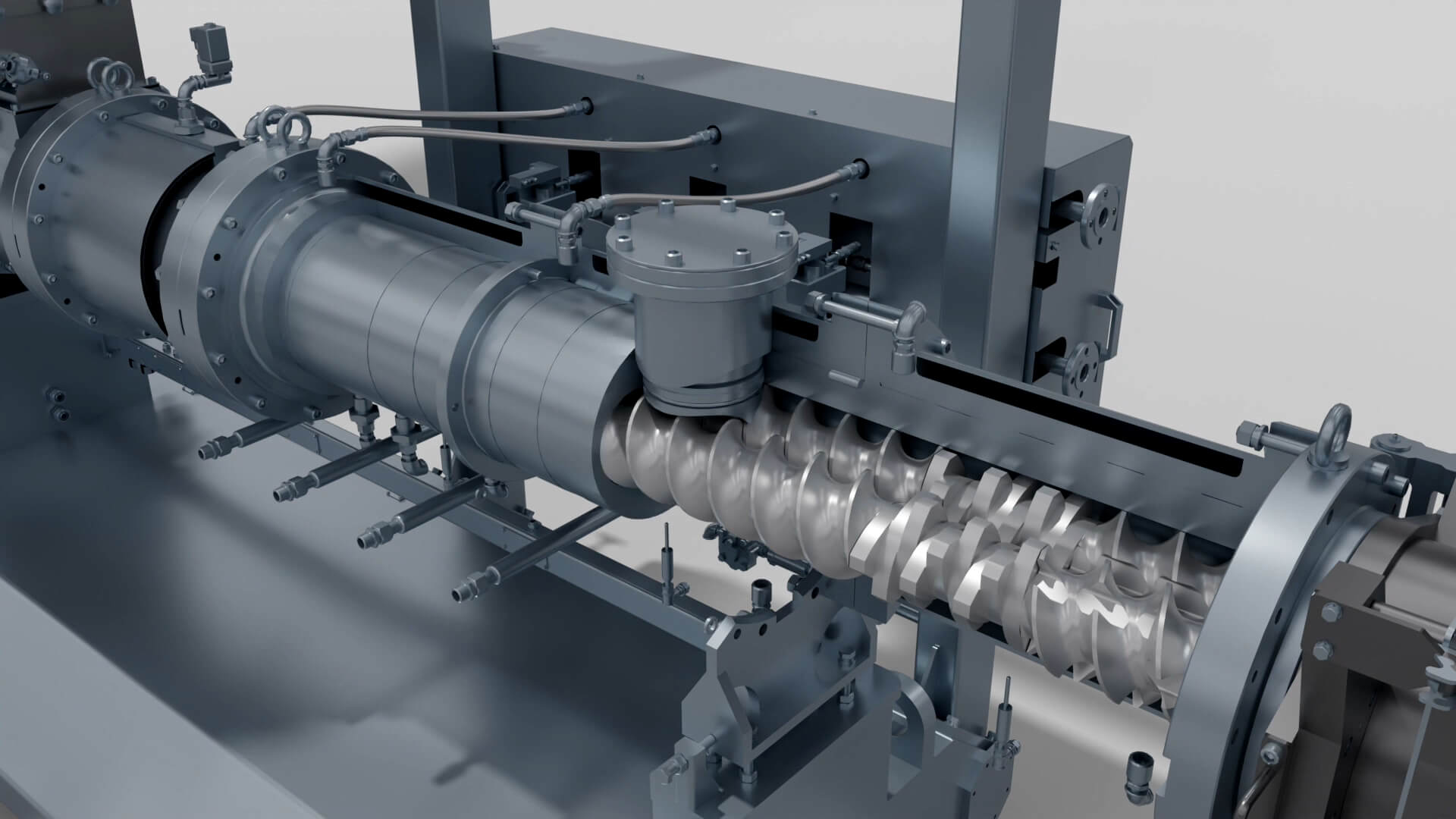

01Stable operation, high capacity and low energy consumption+The SJPS series single-screw aquafeed extruder has an optimal L/D ratio of 13.1:1, with key components like bearings and oil seals sourced from top brand suppliers, ensuring stable operation and longevity. The screw parameters and configuration have been optimized, resulting in a production capacity for floating aquafeed that's over 10% higher than competitors. The power consumption is impressively low, at 20 to 23 kWh per ton of feed.

01Stable operation, high capacity and low energy consumption+The SJPS series single-screw aquafeed extruder has an optimal L/D ratio of 13.1:1, with key components like bearings and oil seals sourced from top brand suppliers, ensuring stable operation and longevity. The screw parameters and configuration have been optimized, resulting in a production capacity for floating aquafeed that's over 10% higher than competitors. The power consumption is impressively low, at 20 to 23 kWh per ton of feed. -

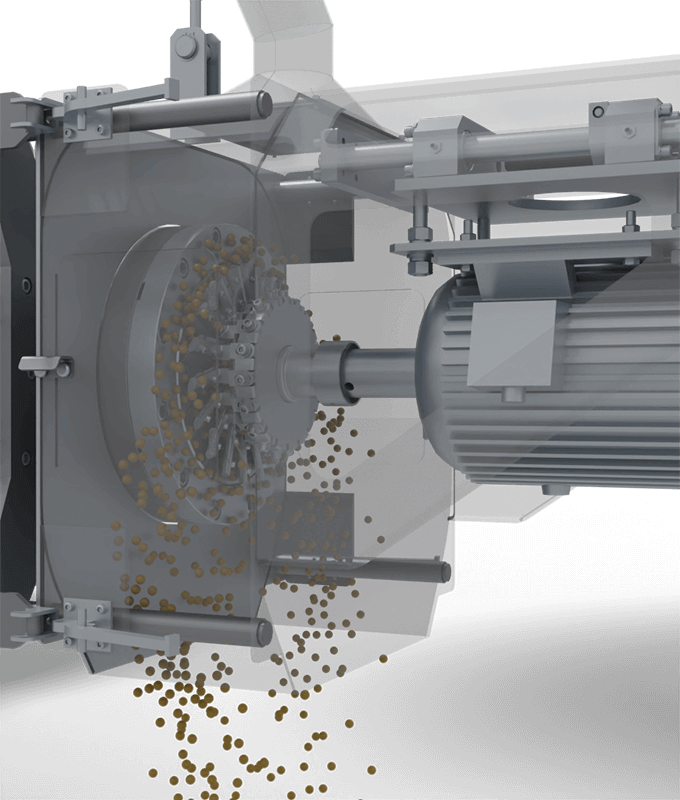

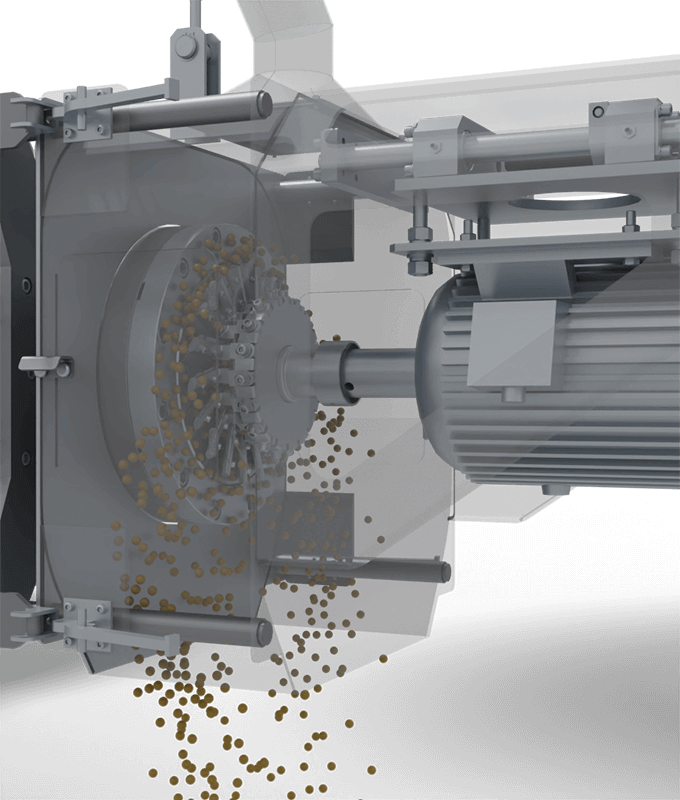

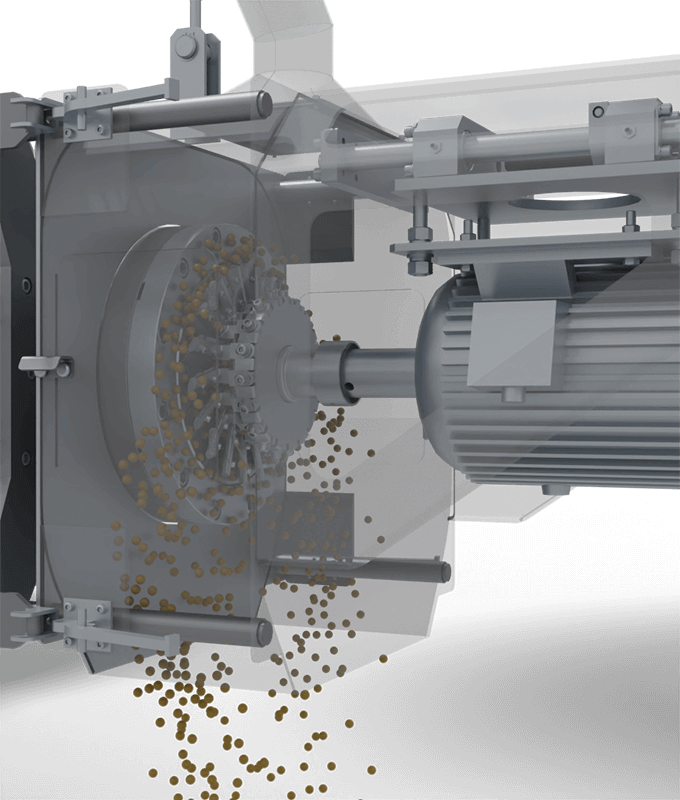

02Uniform pellets, high gelatinization degree, and good appearance+By employing uniform and efficient conditioning technology, screw configuration techniques, and CFD simulation, the discharge device and die hole distribution were optimized. This results in highly uniform extruded pellets, with an expansion coefficient variance of ≤0.1 and a gelatinization degree above 95%.

02Uniform pellets, high gelatinization degree, and good appearance+By employing uniform and efficient conditioning technology, screw configuration techniques, and CFD simulation, the discharge device and die hole distribution were optimized. This results in highly uniform extruded pellets, with an expansion coefficient variance of ≤0.1 and a gelatinization degree above 95%. -

03Wide application range and low production and investment costs+The processing range includes most floating feeds and sinking feeds with high, medium and low-grade formulas, and can also process small floating feeds produced by die of 0.6mm-1mm holes. The production cost and product quality are comparable to those of a twin-screw extruder, and the investment and operation cost is much lower than that of a twin-screw extruder.

03Wide application range and low production and investment costs+The processing range includes most floating feeds and sinking feeds with high, medium and low-grade formulas, and can also process small floating feeds produced by die of 0.6mm-1mm holes. The production cost and product quality are comparable to those of a twin-screw extruder, and the investment and operation cost is much lower than that of a twin-screw extruder. -

04High degree of automation to ensure uniform product quality+Modular intelligent control, independent monitoring of key parameters, high degree of automation. The equipment includes standardized modules like: automatic system feeding, one-click preheating, one-click conditioning, one-click startup for the extruder and auxiliary devices, automatic control of mechanical energy, one-click shutdown, and one-click extruder cleaning. These modules increase automation, thereby decreasing the need for manual labor.

04High degree of automation to ensure uniform product quality+Modular intelligent control, independent monitoring of key parameters, high degree of automation. The equipment includes standardized modules like: automatic system feeding, one-click preheating, one-click conditioning, one-click startup for the extruder and auxiliary devices, automatic control of mechanical energy, one-click shutdown, and one-click extruder cleaning. These modules increase automation, thereby decreasing the need for manual labor.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN