Performance Characteristics

-

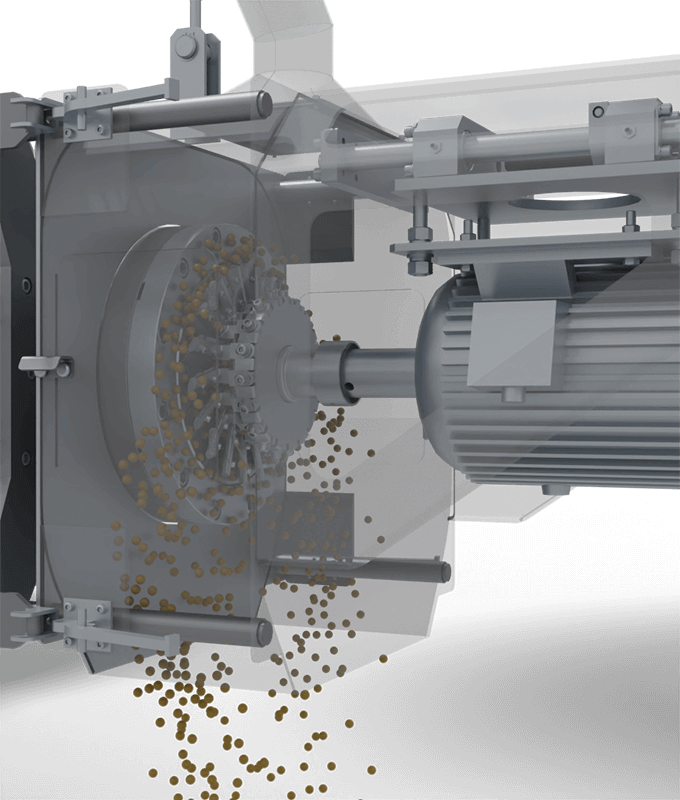

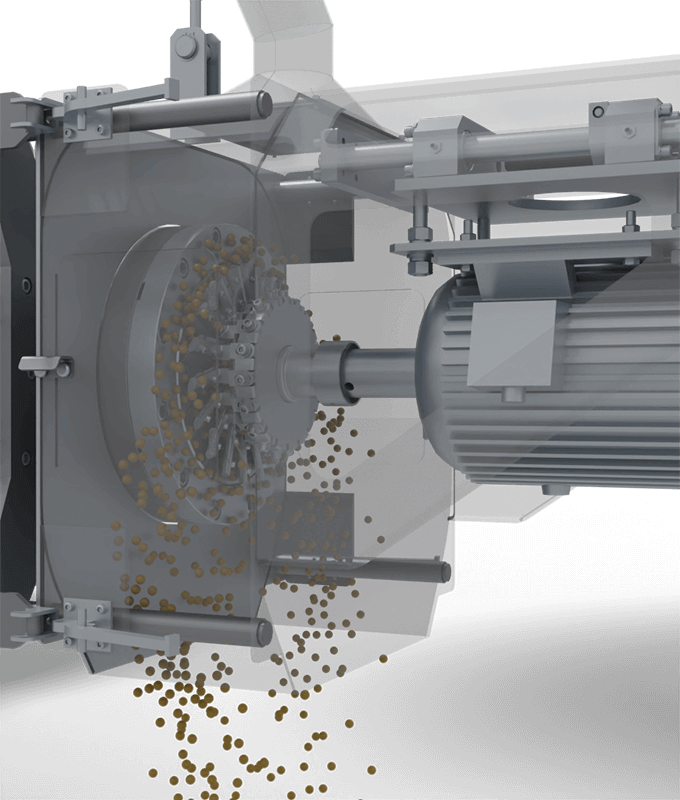

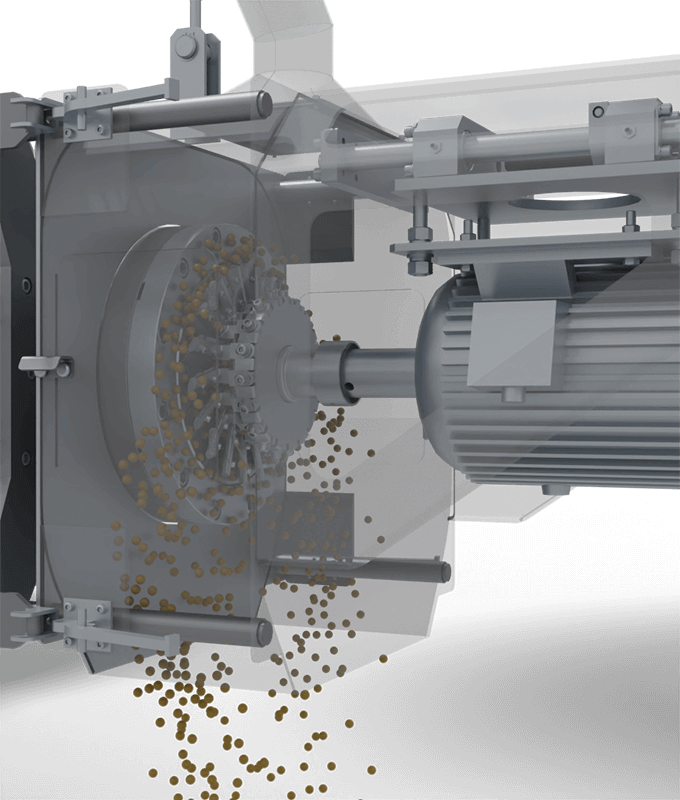

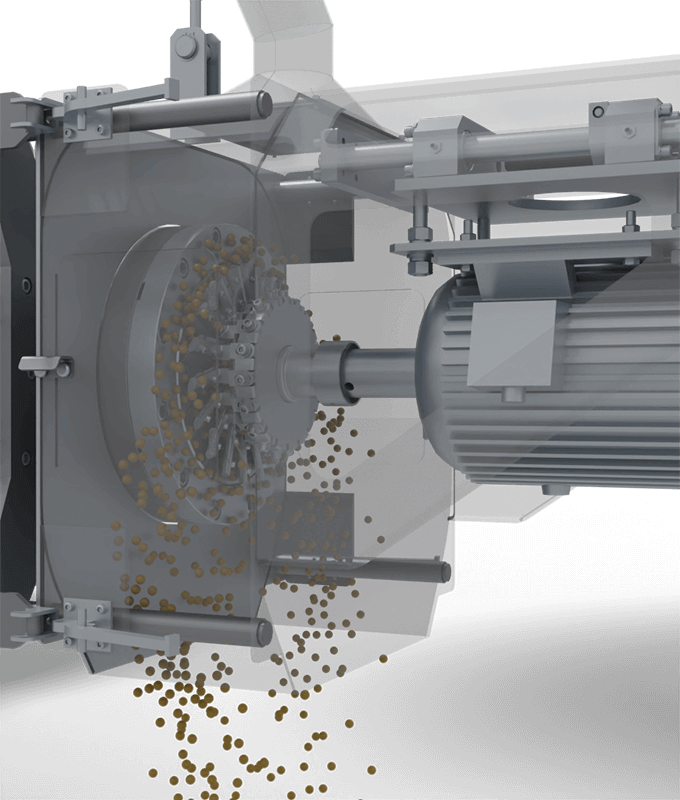

01High Production Capacity and Low Energy Consumption+Based on the specific requirements of pig feed, poultry feed, and aquafeed, the screw length-to-diameter (L/D) ratio and screw configuration are tailored to optimize quality while minimizing energy use. This optimization can boost the production capacity of the pelleting line by up to 20%-30%.

01High Production Capacity and Low Energy Consumption+Based on the specific requirements of pig feed, poultry feed, and aquafeed, the screw length-to-diameter (L/D) ratio and screw configuration are tailored to optimize quality while minimizing energy use. This optimization can boost the production capacity of the pelleting line by up to 20%-30%. -

02High Starch Gelatinization with Low Powder Content+Effectively improves the gelatinization degree of starch (reaching 40-75% of pig feed, 35-60% of poultry feed and 35-55% of aquafeed), and reduces the powder content, improves the feed digestion and utilization rate, widens the selection range of formula raw materials and reduces the formula cost.

02High Starch Gelatinization with Low Powder Content+Effectively improves the gelatinization degree of starch (reaching 40-75% of pig feed, 35-60% of poultry feed and 35-55% of aquafeed), and reduces the powder content, improves the feed digestion and utilization rate, widens the selection range of formula raw materials and reduces the formula cost. -

03Excellent Automation Control System+One-click operation streamlines the process, reducing labor intensity. The precise control offered by automation minimizes human error on production parameters and product quality, thereby increasing production efficiency.

03Excellent Automation Control System+One-click operation streamlines the process, reducing labor intensity. The precise control offered by automation minimizes human error on production parameters and product quality, thereby increasing production efficiency. -

04Safe, Stable, and User-Friendly+Core components are sourced from leading brand suppliers to guarantee safe and stable equipment operation. The screw, manufactured using advanced technology, extends service life by 2.5 to 3 times, significantly reducing maintenance and replacement costs.

04Safe, Stable, and User-Friendly+Core components are sourced from leading brand suppliers to guarantee safe and stable equipment operation. The screw, manufactured using advanced technology, extends service life by 2.5 to 3 times, significantly reducing maintenance and replacement costs.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN