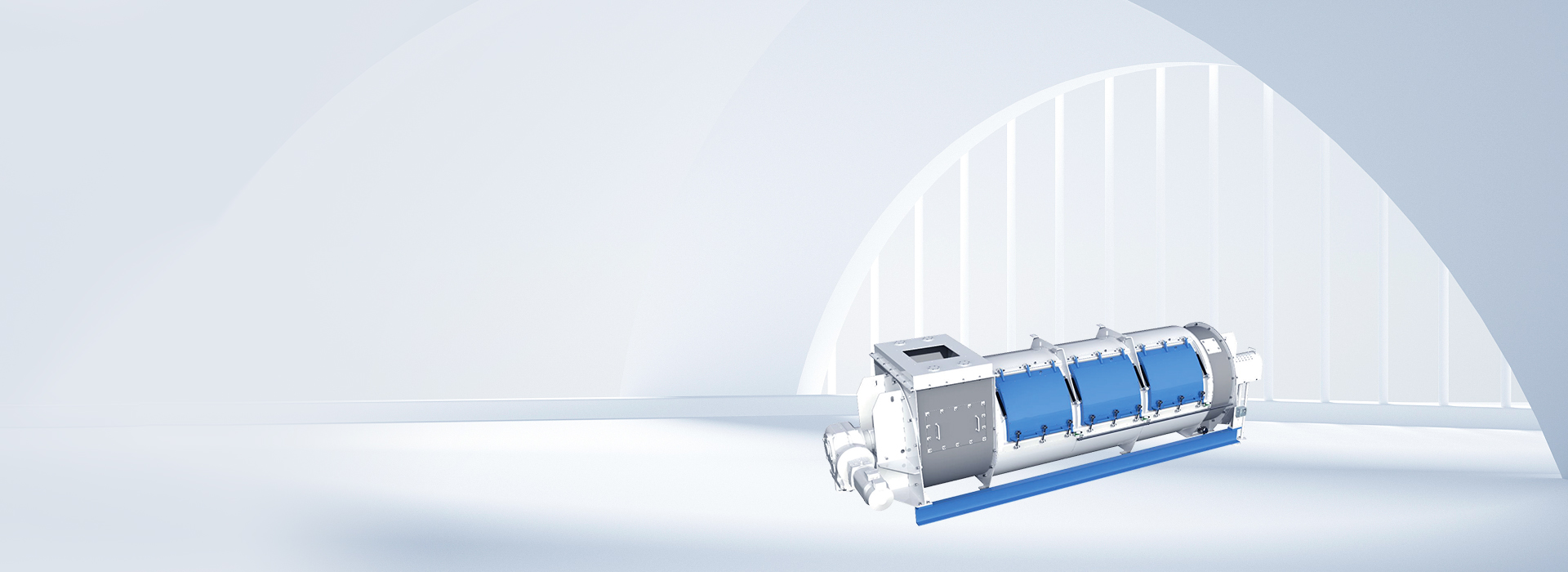

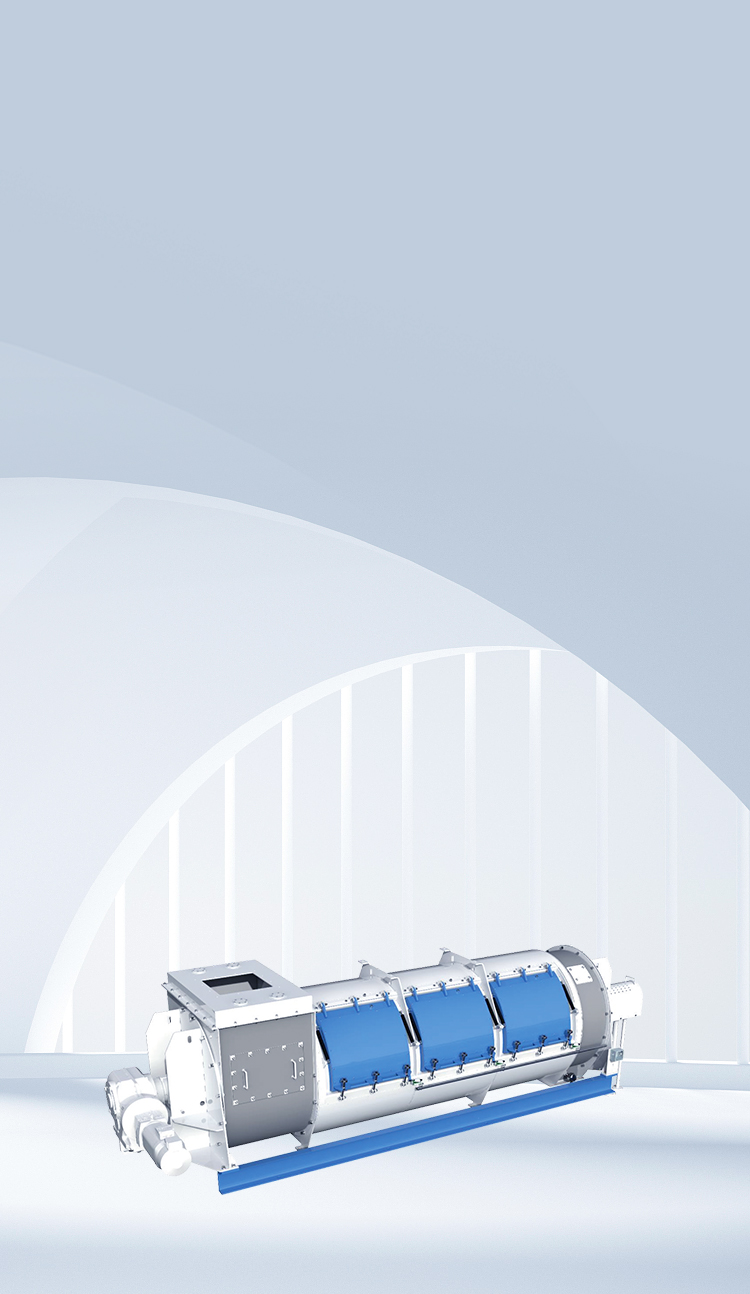

Performance Characteristics

-

01Flexible Process Configuration+Standardized interface design, can be freely combined with conventional conditioning equipment;

01Flexible Process Configuration+Standardized interface design, can be freely combined with conventional conditioning equipment;

Speed adjustable with VFD to adapt to various working conditions, with a maximum material fill rate of 70%. -

02Efficient and Hygienic+Full screw rotor, first-in-first-out, uniform moisture distribution, low residue;

02Efficient and Hygienic+Full screw rotor, first-in-first-out, uniform moisture distribution, low residue;

All parts in contact with the material are made of food-grade stainless steel, meeting hygiene standards. -

03Precise Temperature Control+Full coverage electric heating jacket on the shell and doors, equipped with an intelligent temperature control system, rapid heating, precise temperature control, safe and reliable;

03Precise Temperature Control+Full coverage electric heating jacket on the shell and doors, equipped with an intelligent temperature control system, rapid heating, precise temperature control, safe and reliable;

Thickened insulation layer, filled with high-quality flame-retardant insulation material, minimal heat loss, energy-saving and consumption-reducing. -

04Easy Operation+Large maintenance door design, supported by double gas springs, stable and reliable, easy for maintenance and cleaning;

04Easy Operation+Large maintenance door design, supported by double gas springs, stable and reliable, easy for maintenance and cleaning;

Multi-functional locking handle, balancing operational flexibility and safety. -

05Configuration Upgrade+Upgraded transmission system, improved reliability and ease of maintenance;

05Configuration Upgrade+Upgraded transmission system, improved reliability and ease of maintenance;

New material distribution mechanism, reducing discharge fluctuation, uniformity increased by 50%;

Optional rotor steam heating function, solving the issue of insufficient conditioning temperature in low-temperature environments.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN