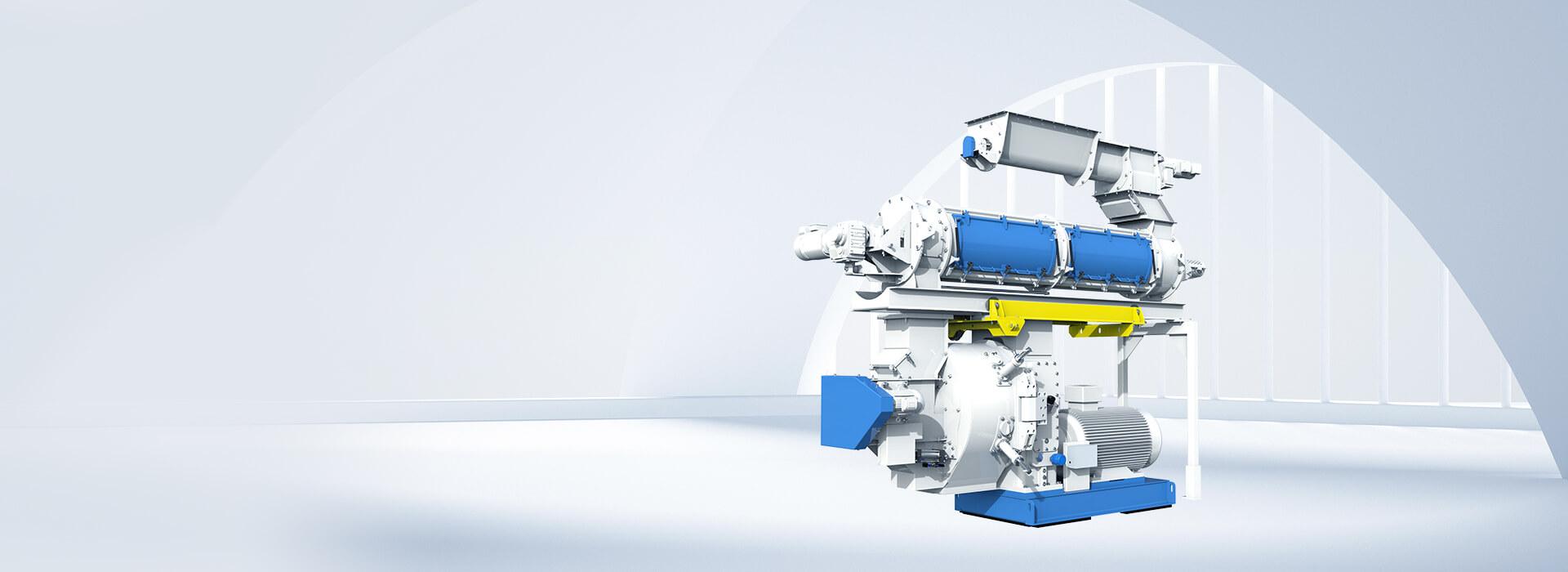

Performance Characteristics

-

01High Quality Production+Precise full-system moisture control and effective utilization of steam (with a measured steam utilization rate>92%) ensure the quality and capacity of the pelleting system.

01High Quality Production+Precise full-system moisture control and effective utilization of steam (with a measured steam utilization rate>92%) ensure the quality and capacity of the pelleting system.

The application of forced feeding technology and special roll configurations guarantees the high hardness requirements for ruminant pellets.

The design of high-strength ring dies increases power per unit area by 15%, further enhancing pellet quality. -

02Enhance Efficiency+Adjustments are made regionally and seasonally based on formulas and production modes to ensure efficient production of ruminant feed.

02Enhance Efficiency+Adjustments are made regionally and seasonally based on formulas and production modes to ensure efficient production of ruminant feed.

The STZN conditioner incorporates steam addition internally from the rotor, preventing steam overflow and diffusion and ensuring steam gets complete contact with and absorbed by the material.

An external liquid addition system, complemented by molasses and two-fluid addition technology, satisfies varying liquid addition requirements.

The application of automation, such as automatic lubrication and electric lifting, significantly reduces labour costs and enhances production efficiency.

The application of forced feeding technology and special roll configurations allows for the smooth compression of low-bulk-density and complex materials.

A production capacity of 9-12 t/h (with hay powder addition ranging from 20% to 40%) can be achieved, representing an efficiency increase of 15%-20%. -

03Loss Reduction+The ring die and rolls are the major contributors to wear and tear costs in the pellet mill, accounting for over 50% of the total loss costs within the pelleting system. The application of specialized ruminant ring die and rolls has reduced the frequency of replacements, enabling you to save hundreds of thousands of yuan annually.

03Loss Reduction+The ring die and rolls are the major contributors to wear and tear costs in the pellet mill, accounting for over 50% of the total loss costs within the pelleting system. The application of specialized ruminant ring die and rolls has reduced the frequency of replacements, enabling you to save hundreds of thousands of yuan annually.

The use of specialized wear-resistant picks on conditioners and deflectors on pellet mills for ruminant recipes containing high fiber has reduced the frequency of replacements, lowering operational costs. Overall, operational costs can be decreased by more than 10%. -

04Intelligent Operation+The application of technologies such as automatic lubrication for the pellet mill's main shaft and rolls, as well as automatic adjustment of gap between rolls and the ring die, reduces labour intensity while enhancing production efficiency.

04Intelligent Operation+The application of technologies such as automatic lubrication for the pellet mill's main shaft and rolls, as well as automatic adjustment of gap between rolls and the ring die, reduces labour intensity while enhancing production efficiency.

The conditioner features self-cleaning cylinder walls and rotors, facilitating the easy removal of residues and minimizing the time wasted on manual cleaning.

Minimizing manual operations ensures the automated operation of the equipment.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN