Performance Characteristics

-

01Demand-Pull production (Automatic Scheduling of the Production Process)+Demand-Pull Production for Enhanced Efficiency

01Demand-Pull production (Automatic Scheduling of the Production Process)+Demand-Pull Production for Enhanced Efficiency

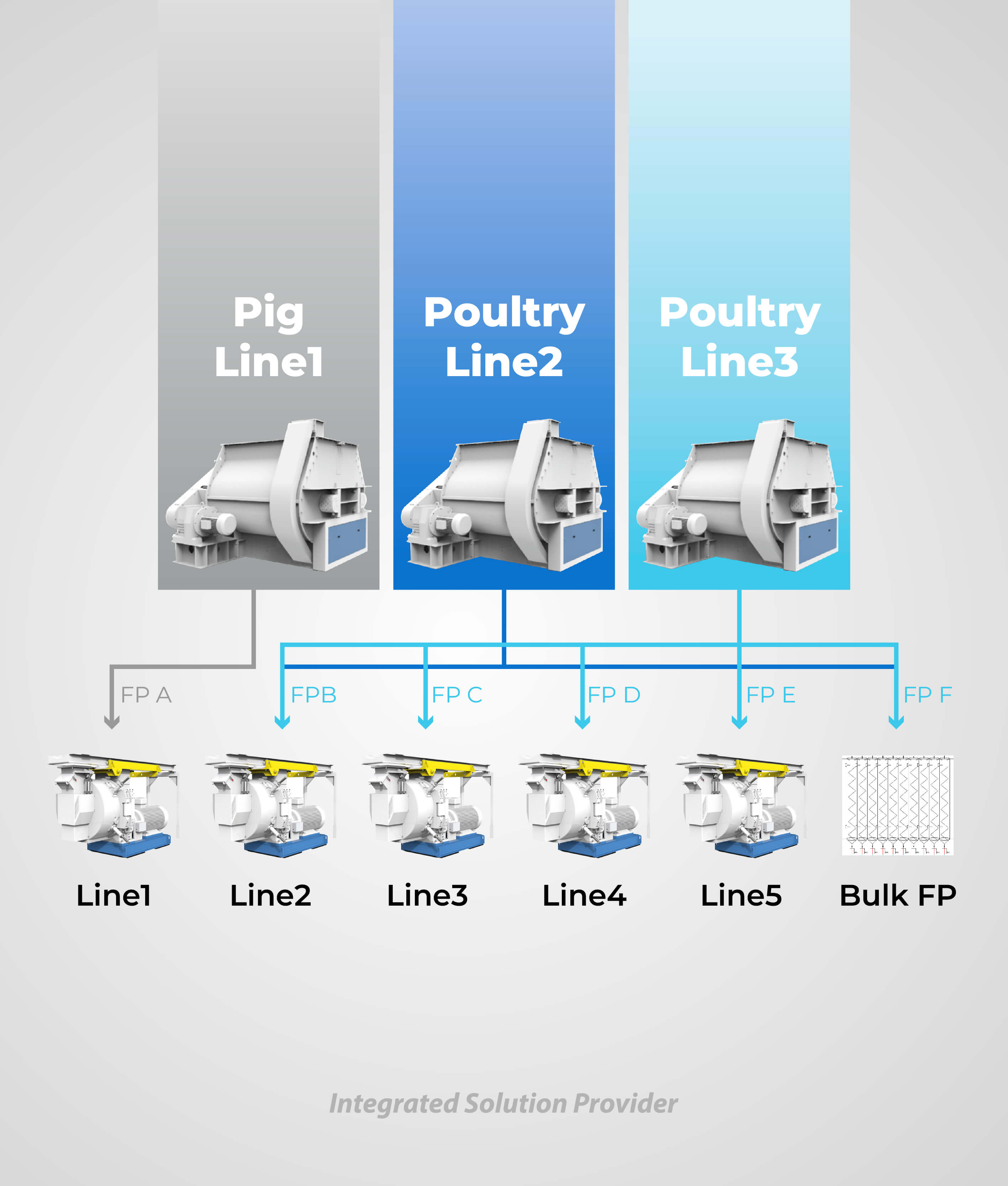

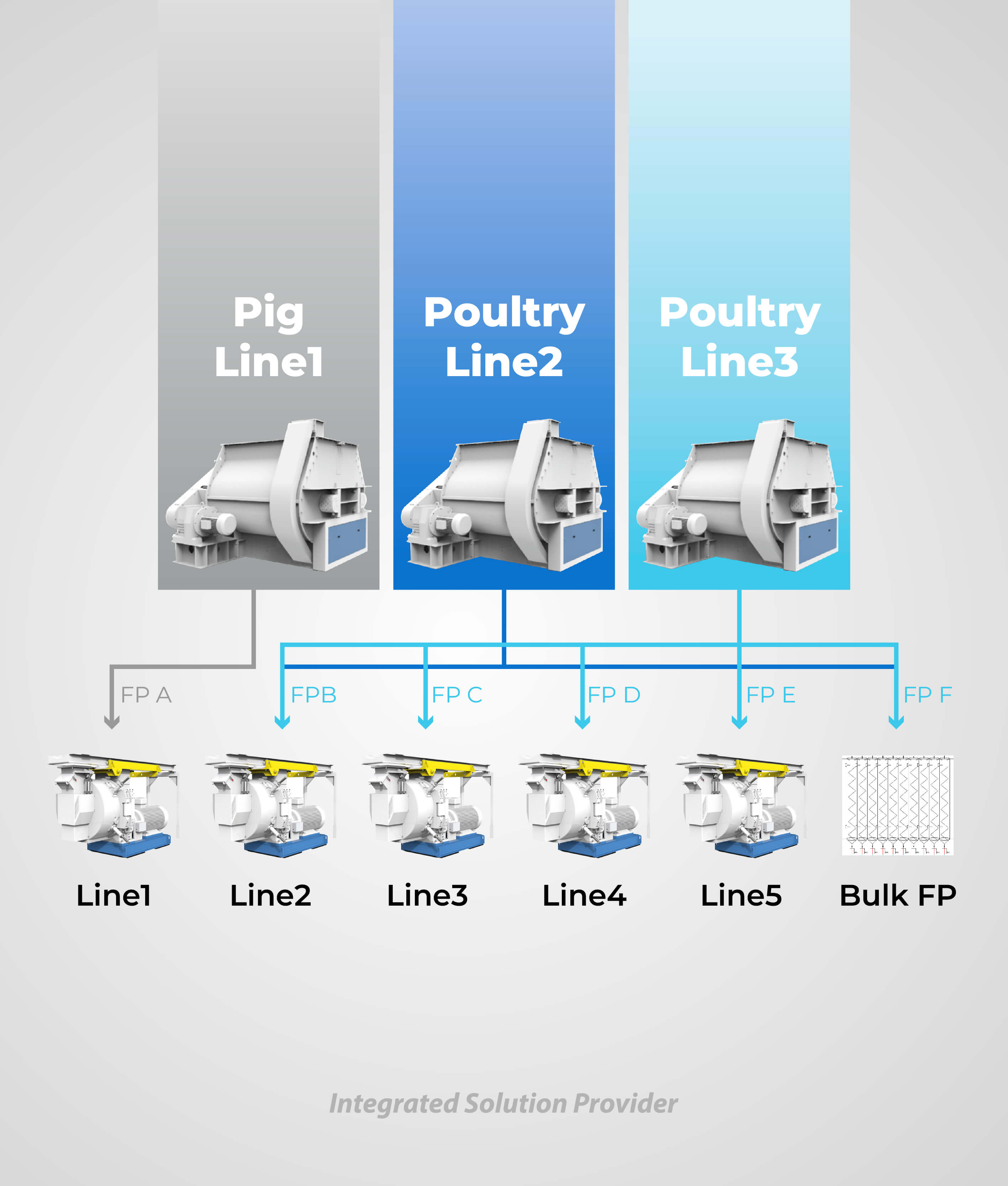

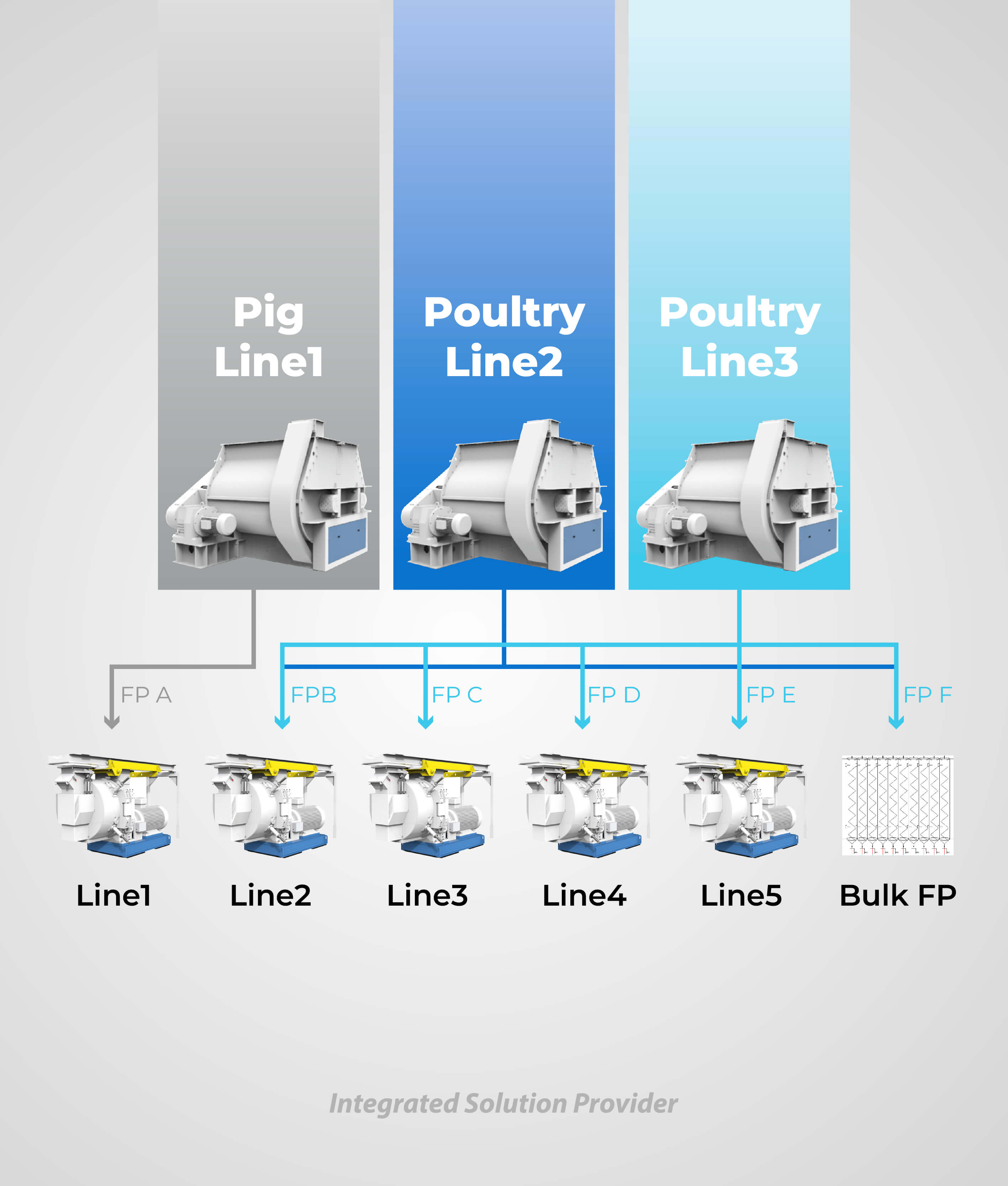

Demand-pull production is a demand-driven approach that adjusts material supply based on the production plan, optimizing overall production efficiency. In the FimCOS system, demand-pull production is implemented through precise guidance from the production scheduling system. This system dynamically adjusts replenishment plans for each storage bin in real-time, based on actual order demands, ensuring a continuous production flow without interruptions due to material shortages.

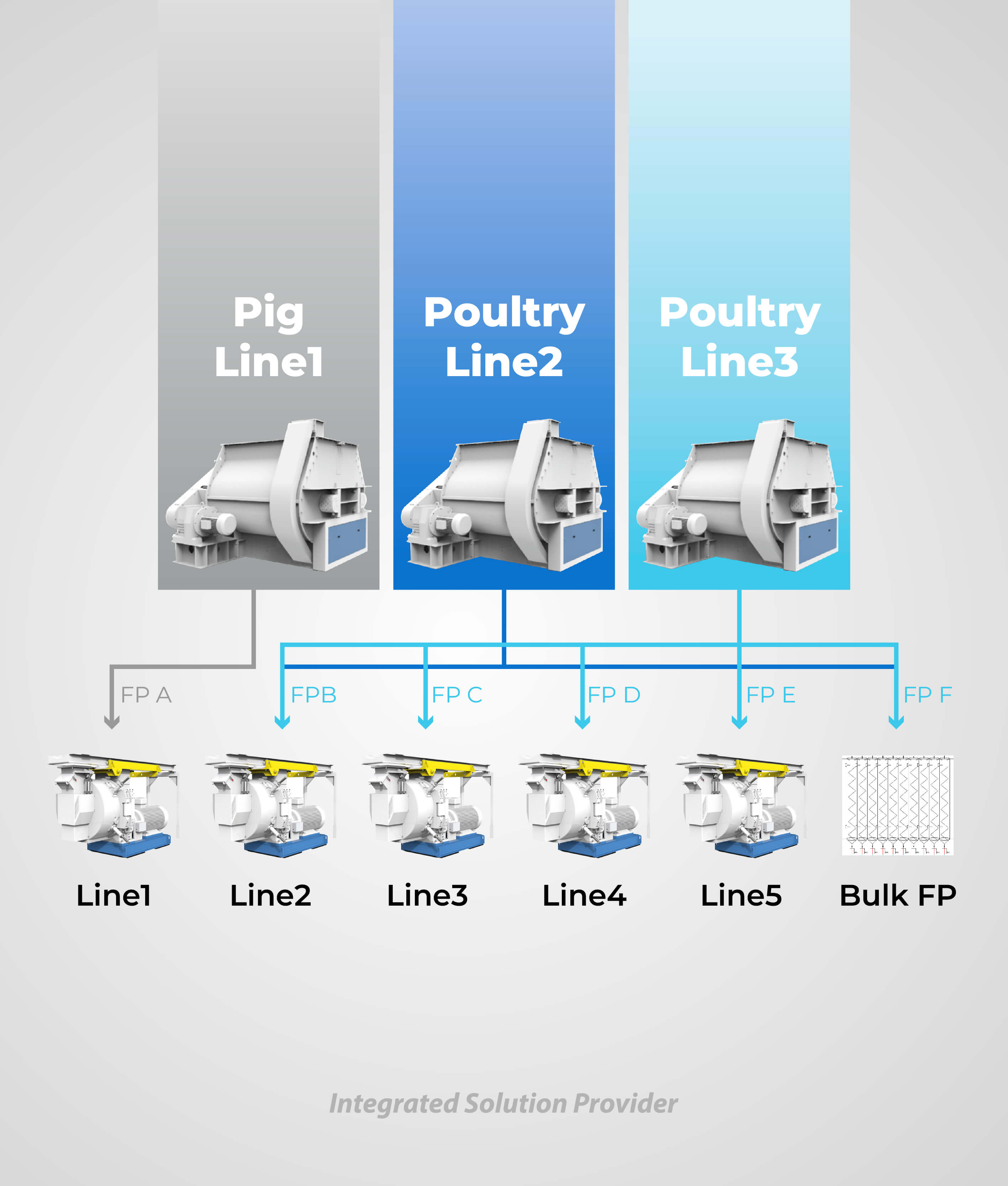

Balanced Material Supply for Optimal Production Flow

Balanced material supply ensures a harmonious match between material supply and consumption throughout the production process, especially in scenarios involving multiple production lines and formulas. The FimCOS system continuously monitors the material consumption rate at each production step, adjusting the upstream supply speed to maintain a smooth material flow. By leveraging intelligent algorithms to optimize material allocation, the system prevents downtime caused by imbalances in supply. During material replenishment, the system automatically identifies and adjusts the supply ratio between different materials, adapting to the specific needs of various product formulas.

-

02Automatic Batching Dosing+Dynamic Parameter Optimization: Leveraging AI-powered discharge compensation algorithms, the system dynamically optimizes ingredient parameters to minimize dynamic errors and maximize efficiency.

02Automatic Batching Dosing+Dynamic Parameter Optimization: Leveraging AI-powered discharge compensation algorithms, the system dynamically optimizes ingredient parameters to minimize dynamic errors and maximize efficiency.

Customizable Discharge Sequence: Tailor ingredient discharge sequences to meet specific production requirements.

Recipe Security Management: Role-based access control restricts unauthorized personnel from viewing recipe details or material data, ensuring IP protection.

Automatic Cleaning Function: Post-production auto-cleaning eliminates cross-contamination risks.

Continuous Batch Production: Adjust follow-up batch recipes mid-process to enable uninterrupted multi-recipe, multi-batch workflows.

Emergency Order Insertion: Prioritize urgent orders without disrupting scheduled tasks, with automatic resumption of interrupted workflows.

Fault Recovery Function: Auto-resume interrupted ingredient plans after power outages, system crashes, or unexpected reboots.

Online Auto-Calibration: Enable unmanned calibration via built-in mechanisms, achieving real-time precision validation without manual weight handling. -

03Automatic Finished Product Shipping+Bagged Products: System generates packaging tasks (product type, specifications, target quantity). Workers execute tasks via on-site terminals with real-time progress tracking. Palletizing entry counters sync finished goods data with ERP systems.

03Automatic Finished Product Shipping+Bagged Products: System generates packaging tasks (product type, specifications, target quantity). Workers execute tasks via on-site terminals with real-time progress tracking. Palletizing entry counters sync finished goods data with ERP systems.

Bulk Products: Fully unmanned bulk handling via integration with digital one-code systems, covering inbound to outbound processes. -

04Multi-System Integration+FimCOS seamlessly integrates with third-party systems (e.g., liquid egg, choline, and spray coating equipment), enabling centralized control and eliminating multi-platform management. This integration streamlines workflows and boosts production efficiency by over 30%.

04Multi-System Integration+FimCOS seamlessly integrates with third-party systems (e.g., liquid egg, choline, and spray coating equipment), enabling centralized control and eliminating multi-platform management. This integration streamlines workflows and boosts production efficiency by over 30%.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN