Performance Characteristics

-

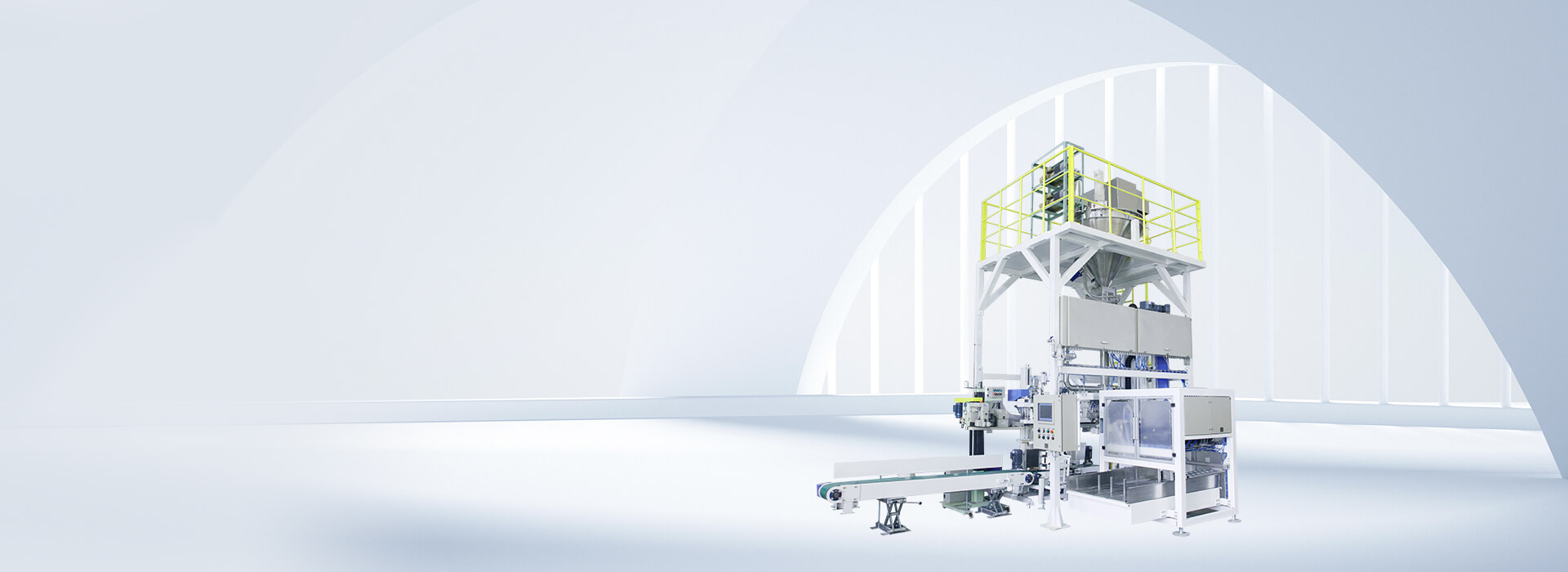

01High Weighing Accuracy+Adopting dynamic weighing technology, combined with fast and slow feeding switching and feeding ring gap size switching, it ensures production capacity while ensuring the accuracy of weighing, with the highest accuracy reaching ±10g (±0.4‰).

01High Weighing Accuracy+Adopting dynamic weighing technology, combined with fast and slow feeding switching and feeding ring gap size switching, it ensures production capacity while ensuring the accuracy of weighing, with the highest accuracy reaching ±10g (±0.4‰). -

02High Production Efficiency+Adopting the design concept of “workstation separation,” multiple workstations operate in parallel, combined with “high-speed screw feeding technology,” “stirring-guided discharge technology,” and “feeding ring gap size switching technology,” to maximize production capacity. The powder packaging speed can reach up to more than 200 bags/h.

02High Production Efficiency+Adopting the design concept of “workstation separation,” multiple workstations operate in parallel, combined with “high-speed screw feeding technology,” “stirring-guided discharge technology,” and “feeding ring gap size switching technology,” to maximize production capacity. The powder packaging speed can reach up to more than 200 bags/h. -

03Dust Free Production+Using a screw feeding method, combined with a lifting and weighing system, to prevent the occurrence of “powder spraying” during feeding; establishing a centralized dust removal port to achieve a dust-free production process.

03Dust Free Production+Using a screw feeding method, combined with a lifting and weighing system, to prevent the occurrence of “powder spraying” during feeding; establishing a centralized dust removal port to achieve a dust-free production process. -

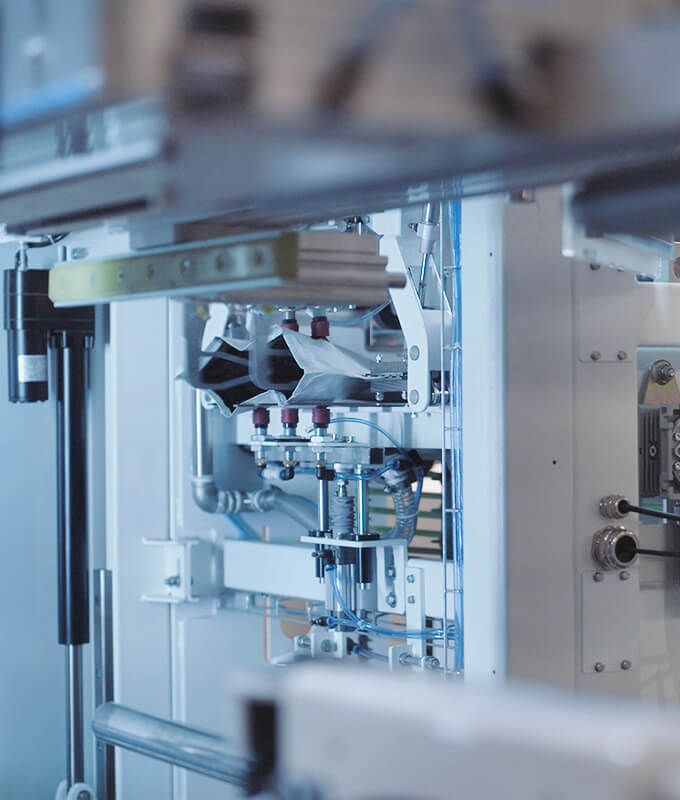

04Multi-Stage Exhaust Process+The three-stage exhaust process: conveying degassing in the spiral cylinder, vibration exhaust, and roller exhaust, thoroughly removing the air inside the bag for easy stacking.

04Multi-Stage Exhaust Process+The three-stage exhaust process: conveying degassing in the spiral cylinder, vibration exhaust, and roller exhaust, thoroughly removing the air inside the bag for easy stacking. -

05Easy to Clean with Water+Suitable for multiple formula requirements, preventing cross-contamination. The entire water washing process can be completed in just 10 minutes.

05Easy to Clean with Water+Suitable for multiple formula requirements, preventing cross-contamination. The entire water washing process can be completed in just 10 minutes. -

06One-click switching for multiple formulas+According to the material properties, preset formulas, automatically adjust the feeding process parameters, automatically adjust the bag length and universal width capability, screen operation, one-click switching.

06One-click switching for multiple formulas+According to the material properties, preset formulas, automatically adjust the feeding process parameters, automatically adjust the bag length and universal width capability, screen operation, one-click switching.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN