Performance Characteristics

-

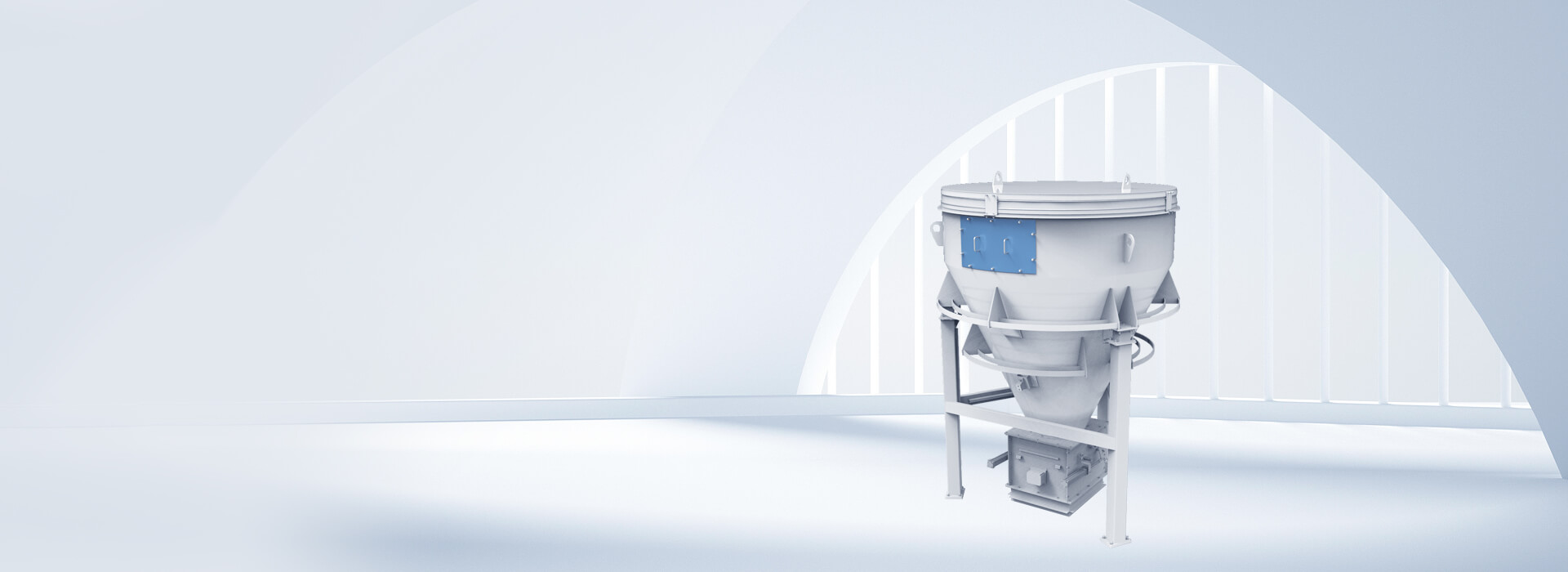

01High-Quality Production+The batch weighing capacities from 150 to 4000kg are available, with a refined equipment range to guarantee the precision of micro ingredients weighing.

01High-Quality Production+The batch weighing capacities from 150 to 4000kg are available, with a refined equipment range to guarantee the precision of micro ingredients weighing.

Adopting Toledo brand sensors: the conventional configuration uses TSC/TSB model sensors, and weighing module sensors can also be optionally equipped. With a precision grade of C3, it can achieve a static accuracy of ±0.1% and a dynamic accuracy of ±0.3% for the scale body, ensuring measurement accuracy.

The scale body is designed with a 65° cone angle, and can be optionally equipped with a pneumatic hammer or vibrator to ensure minimal residue in the scale body. -

02Easy to Install+According to the customer’s equipment layout, the batching hopper can be chosen with a support or suspension structure, making installation and arrangement convenient.

02Easy to Install+According to the customer’s equipment layout, the batching hopper can be chosen with a support or suspension structure, making installation and arrangement convenient. -

03Optional Discharge Door Structures+For conventional feed formulas, a square scale door discharge can be selected. The standard cylinder brand is Hengli, with options for SMC and Festo brands.

03Optional Discharge Door Structures+For conventional feed formulas, a square scale door discharge can be selected. The standard cylinder brand is Hengli, with options for SMC and Festo brands.

For formulas with high bulk density, such as stone powder or calcium hydroxide, a butterfly valve discharge can be chosen. The standard butterfly valve brand is WAM, with customization available for other brands.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN