Performance Characteristics

-

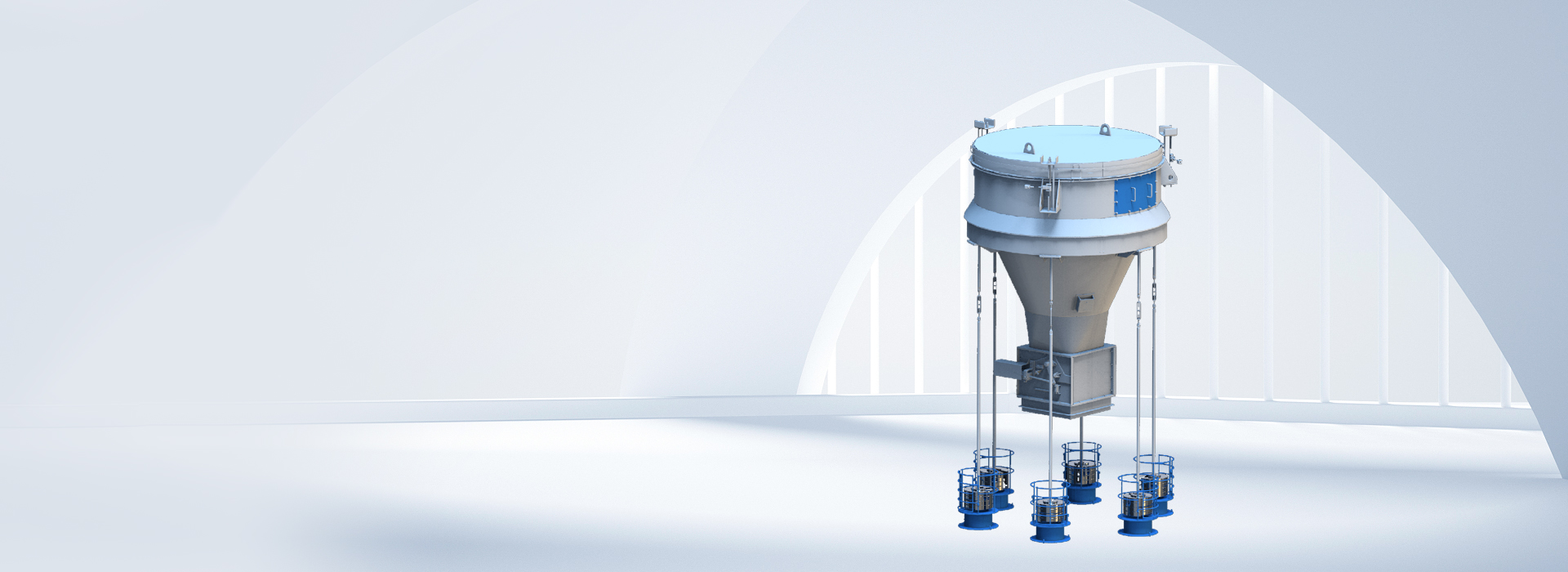

01High-Quality Production+Batch weighing capacities range from 500 to 3000 kg, with a refined equipment range to ensure precise weighing of micro ingredients.

01High-Quality Production+Batch weighing capacities range from 500 to 3000 kg, with a refined equipment range to ensure precise weighing of micro ingredients.

Adopting Toledo brand sensors: the conventional configuration uses TSC/TSB model sensors, and weighing module sensors can also be optionally equipped. With a precision grade of C3, it can achieve a static accuracy of ±0.1% and a dynamic accuracy of ±0.3% for the scale body, ensuring measurement accuracy.

The scale body is designed with a 65° cone angle, and can be optionally equipped with an pneumatic hammer or vibrator to ensure minimal residue in the scale body. -

02Easy to Install+Based on the customer's equipment layout, the batching hopper can be selected with either a support or suspension structure, which allows it to be disassembled for easy on-site installation and facilitates convenient arrangement.

02Easy to Install+Based on the customer's equipment layout, the batching hopper can be selected with either a support or suspension structure, which allows it to be disassembled for easy on-site installation and facilitates convenient arrangement. -

03Optional Discharge Door Structures+For conventional feed formulas, a square scale door discharge option is available. The standard cylinder brand is Hengli, with optional upgrades to SMC and Festo brands.For formulas with high bulk density, such as stone powder or calcium hydroxide, a butterfly valve discharge can be chosen. The standard butterfly valve brand is WAM, with customization available for other brands.

03Optional Discharge Door Structures+For conventional feed formulas, a square scale door discharge option is available. The standard cylinder brand is Hengli, with optional upgrades to SMC and Festo brands.For formulas with high bulk density, such as stone powder or calcium hydroxide, a butterfly valve discharge can be chosen. The standard butterfly valve brand is WAM, with customization available for other brands. -

04Automatic Calibration+Stability is improved by resolving the occasional errors and inconsistencies in repeatability that are often associated with manual code placement.

04Automatic Calibration+Stability is improved by resolving the occasional errors and inconsistencies in repeatability that are often associated with manual code placement.

Automatic control: flexible settings of the batching scale’s calibration frequency according to production needs; aligning with the industry’s intelligent development direction.

Reducing the extensive span of several hours for calibrating ordinary scales up and down to just 1 minute.

Lowering work intensity and reducing the need for human labor. Traditionally, workers constantly moved weights for scale calibration, but now the calibration automation has improved the working environment.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN