Find the answers you are looking for here

Technology

Grinding

Our high-quality grinding equipment, advanced process design and experienced experts can satisfy your specific grinding requirements. Our grinding equipment family meets various size and capacity requirements and is suitable for aquafeed, pet food, grain processing and by-product grinding processing. Our grinding system helps you improve production efficiency, reduce material waste and achieve high-quality products.

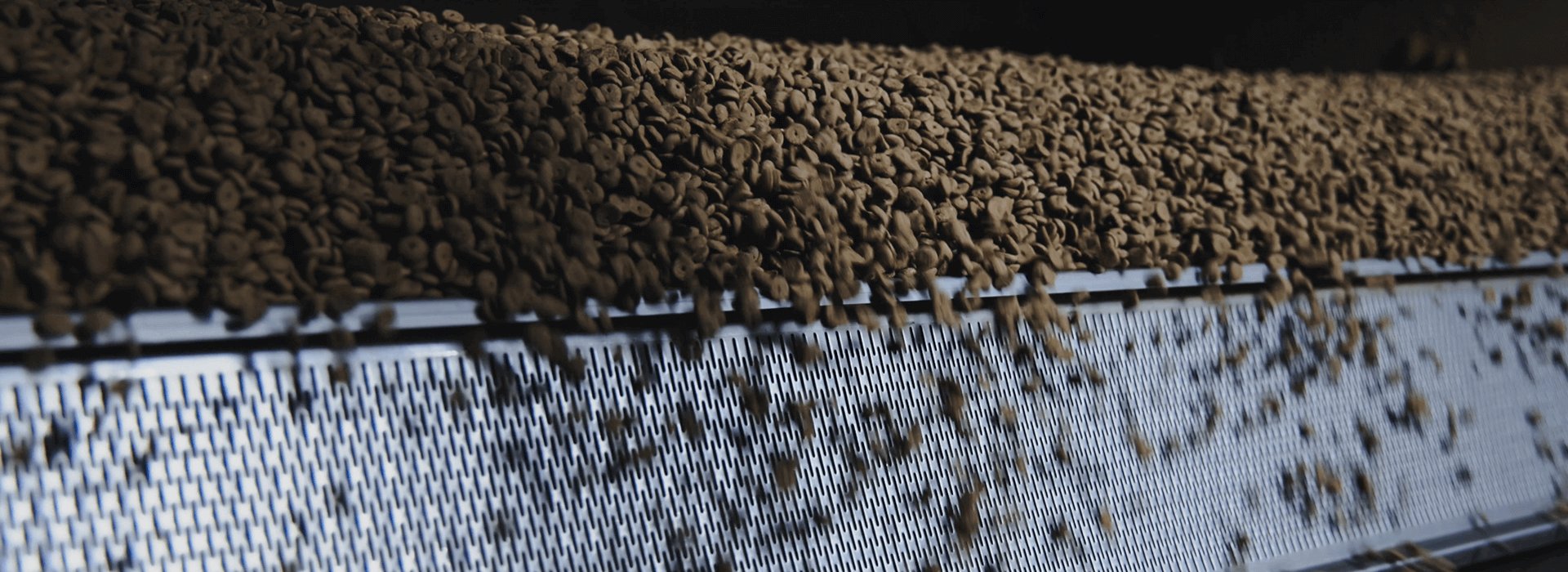

Drying

Our sophisticated drying equipment, advanced process designs, and experienced experts can cater to your specific drying requirements. Our dryer family can meet the requirement of different factory layout and production capacity, catering the drying needs of aquafeed, pet food, grain and its by-products, fermentation products, environmental engineering, and etc. Multiple heat source options are available, such as steam, natural gas, and heat pumps, which comes up with multiple innovative hygienic designs to help you enhance production efficiency, reduce energy waste, and achieve high-quality output.

Pelleting

Our sophisticated pelleting equipment, advanced process design, and experienced experts are here to support and fulfil your specific pelleting requirements. Our series of products cater to diverse sizes and capacity needs. They are suitable for livestock and poultry feed, ruminant feed, aquafeed, pet food, cereal processing, and by-product pelleting. With two transmission options available—gear transmission and belt transmission, FAMSUN can help you enhance production efficiency, reduce waste, and achieve high-quality output.

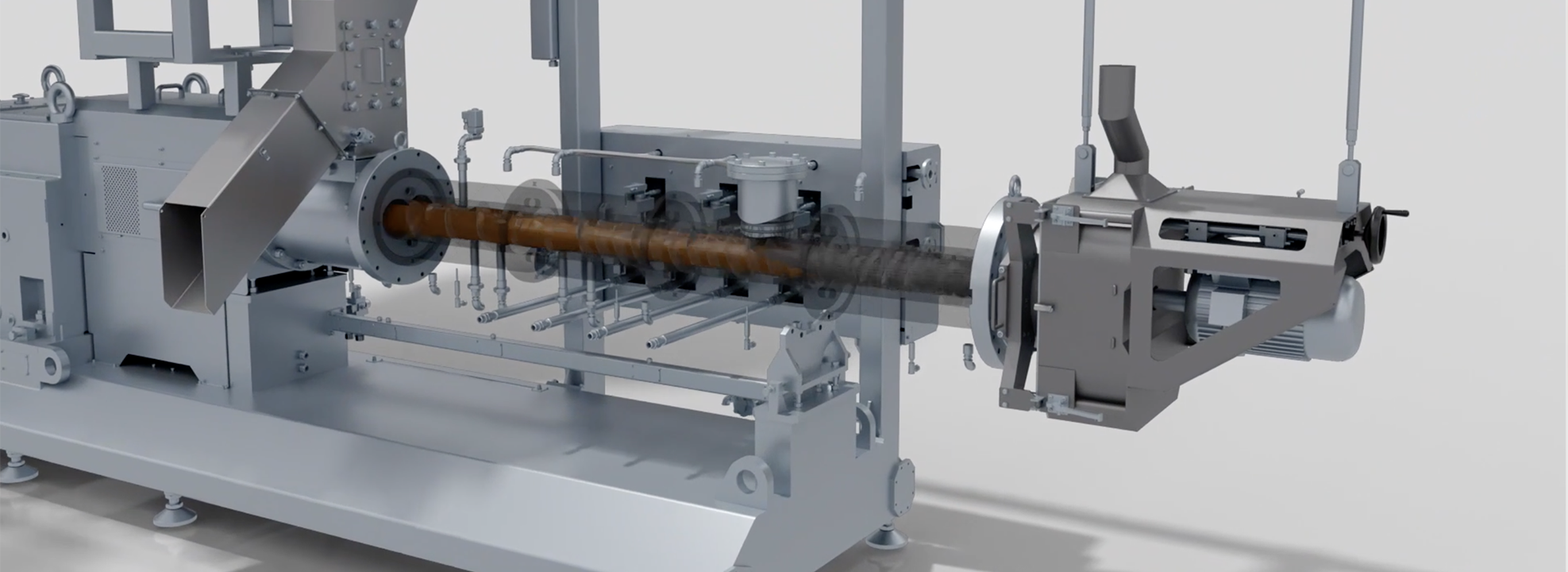

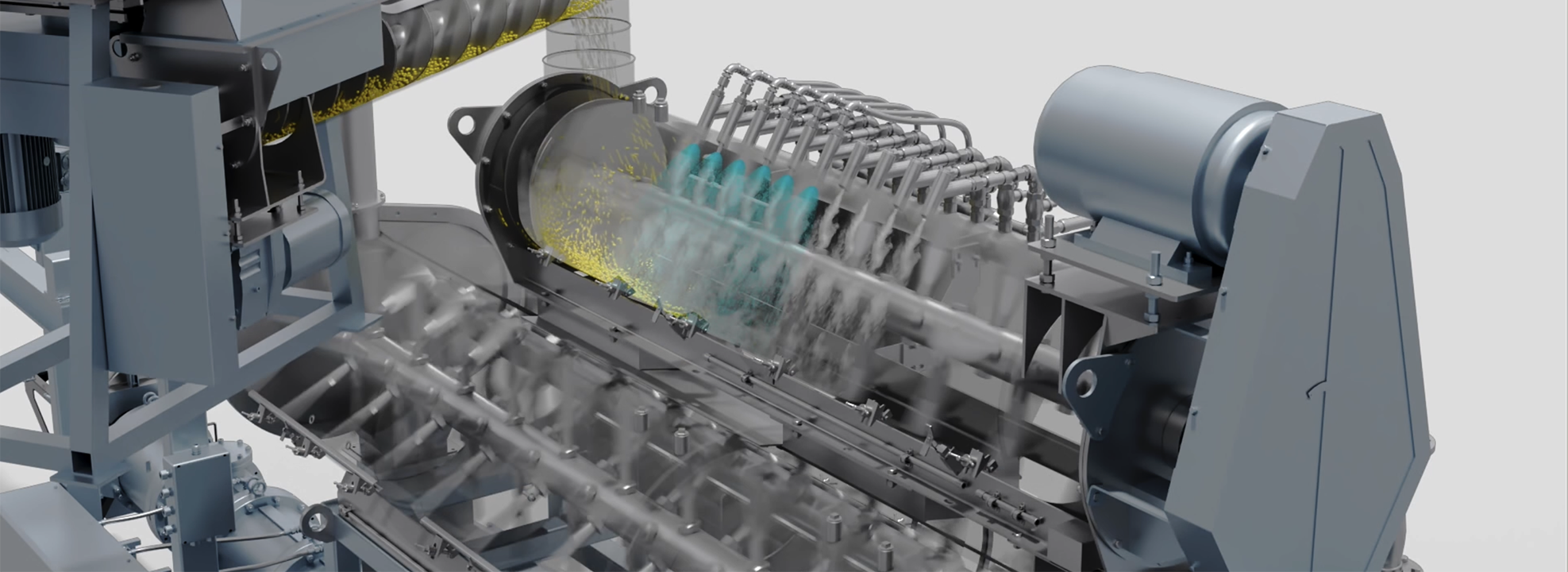

Extrusion

The extrusion process enhances resource utilization, boosts production efficiency, and lowers costs. Extruded products are uniformly shaped, nutritionally balanced, and easily digestible. This technology is extensively applied in manufacturing aquafeed, livestock and poultry feed, pet food, snacks, breakfast cereals, fermented grains, and other products.

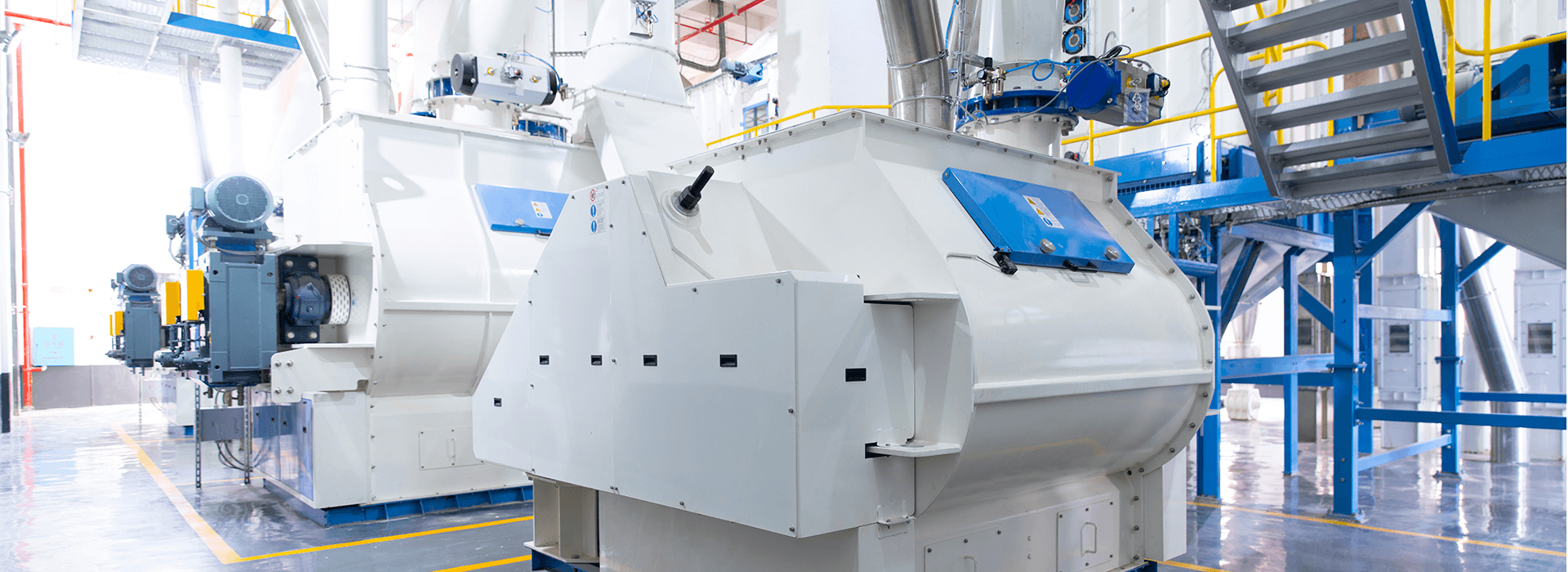

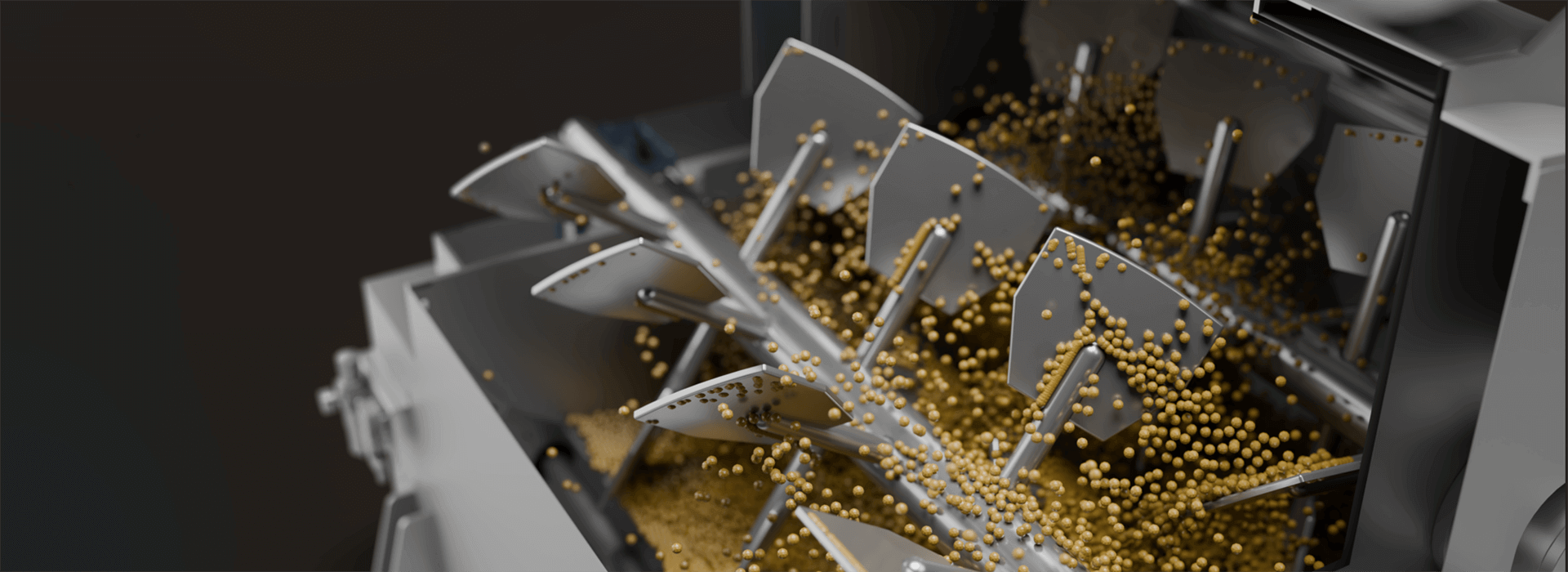

Mixing

Our sophisticated mixing equipment, advanced process design and experienced specialists are at your disposal to meet your specific mixing needs. Our series of products cater for a wide range of sizes and outputs and are suitable for mixing requirements in the processing of pig and poultry feed, aqua feed, pet food, grain and by-products. We offer single-shaft double-paddle mixers, twin-shaft paddle mixers, twin-shaft ribbon mixers and other types to help you improve productivity, reduce waste and achieve high quality output.

Coating

Our sophisticated coating equipment, advanced process design and experienced specialists are at your disposal to meet your specific coating needs. Our series of products cater for a wide range of sizes and outputs and are suitable for coating requirements in the processing of livestock and poultry feed, aqua feed and pet food. We offer vertical normal pressure coating, vertical vacuum coating, horizontal normal pressure coating, horizontal vacuum coating, continuous coating and other types to help you improve productivity, reduce waste and achieve high quality output.

Conditioning

Our state-of-the-art conditioning equipment, combined with advanced process design and the expertise of seasoned professionals, is tailored to meet your specific conditioning requirements. Our product lineup accommodates a wide range of forms and output capacities, ideal for conditioning in the processing of livestock and poultry feed, aquaculture feed, and pet food. We provide an array of conditioner options, including:

• Single-shaft conditioners

• Steam-jacketed conditioners

• No-startup-waste conditioners

• Internal steam-adding conditioners

• Double-shaft differential conditioners (DDC)

Twin-shaft equal-diameter conditioners

• Three-shaft equal-diameter conditioners

For thermal conditioning, our offerings include:

• Steam-jacketed thermal conditioners

• Electric heat thermal conditioners

• Horizontal twin-shaft equal-diameter thermal conditioners

Our conditioning and stabilizing equipment is renowned for its superior performance, enabling you to enhance production efficiency, lower energy consumption, and achieve high-quality outcomes.

Screening

Our precise screening equipment, advanced process design, and team of experienced experts ensure we can meet your unique screening needs. With solutions designed for a wide range of sizes and capacities, our screening equipment is ideal for aquafeed, livestock feed, pet food, premix, grain processing, and byproducts.

We offer screening solutions tailored to various materials, capacities, and requirements, ensuring optimal performance for different scenarios. Customers can select components such as motors, bearings, and sensors from trusted Chinese suppliers or top global brands based on their specific needs, guaranteeing reliable quality and high capacity.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN