Find the answers you are looking for here

Technology

Packaging & Palletizing

We adopt advanced mechanical and electronic equipment to achieve efficient and precise packaging of products. The entire process, including metering, filling, and sealing, is automated, and products are steadily transported to the palletizing area through an intelligent conveying system. The palletizing robot precisely executes tasks such as grabbing, positioning, and stacking through programming, which not only improves efficiency but also reduces labor costs. We provide customized palletizing solution optimization services to ensure that various product characteristics and palletizing requirements are met. Meanwhile, the system monitors the packaging process in real time to ensure stable and reliable quality. We are dedicated to technological innovation, providing customers with efficient and reliable packaging and palletizing solutions to help them enhance their competitiveness.

Liquid Addition

The main contents are as follows:

Liquid transfer pump: It is used to transfer oil or other liquid. According to different requirements of the liquid, different types of transfer pumps can be selected, such as gear pumps, screw pumps, rotor pumps, etc.

Metering device: It is designed with two metering processes, namely flow meters and weight sensors, which are used to accurately measure the quantity of the added liquid.

Agitator: Installed on the tank containing oil or other liquid, it mainly serves to mix different oil or other liquid , and achieves effects such as increasing the heat transfer rate.

Liquid storage tank: Storage tanks of various sizes can be customized according to customers' requirements for storing liquid media. At the same time, various different instruments can be designed and installed on the tank body according to different process requirements.

Control system: It includes control cabinets, PLCs, etc., and precisely controls and regulates the entire liquid addition process.

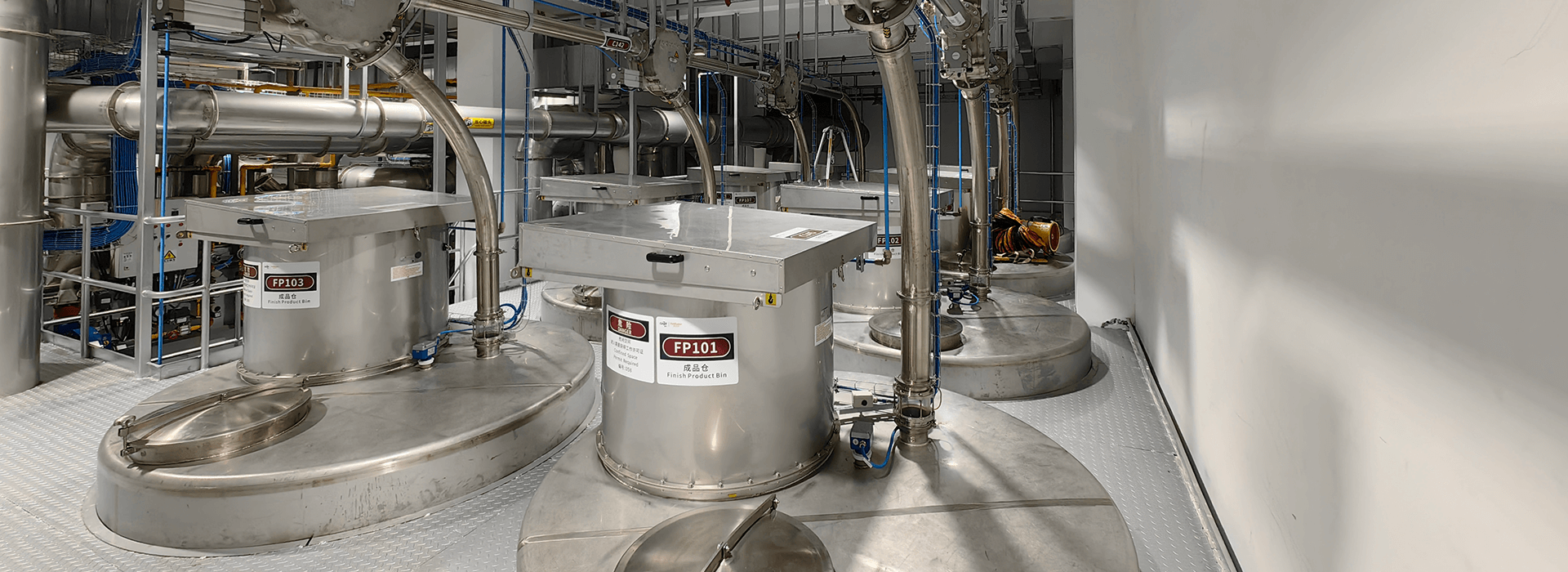

Pneumatic Conveying

Pneumatic conveying is a specific application of fluidization technology, used to transport granular or powdery materials along the direction of airflow in an enclosed pipeline by means of aerodynamic energy. It offers strong flexibility, zero pollution, continuous production, a high level of automation, and easy maintenance. This technology is widely applied in industries such as chemicals, food, mining, and energy.

For example, pneumatic conveying requires minimal space and allows for flexible pipeline layouts, enabling easy navigation through complex terrains and confined spaces, making it highly suitable for mining or renovation projects with challenging landscapes. Additionally, it is clean and hygienic with excellent airtightness, preventing secondary pollution and moisture-induced material degradation, which is particularly advantageous in the food and chemical industries.

In conclusion, pneumatic conveying not only enhances conveying efficiency and reduces investment costs but also effectively addresses material contamination and loss issues during transportation, making it an ideal solution for modern industrial production.

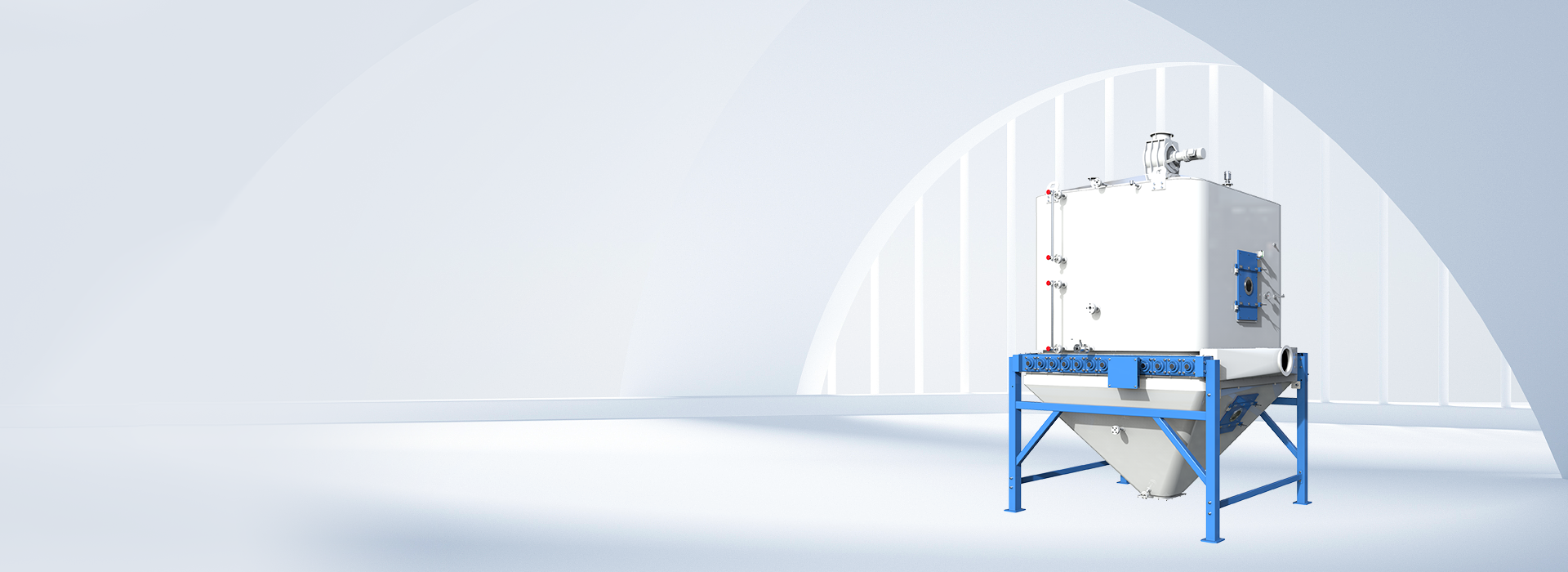

Screening

Our precise screening equipment, advanced process design, and team of experienced experts ensure we can meet your unique screening needs. With solutions designed for a wide range of sizes and capacities, our screening equipment is ideal for aquafeed, livestock feed, pet food, premix, grain processing, and byproducts.

We offer screening solutions tailored to various materials, capacities, and requirements, ensuring optimal performance for different scenarios. Customers can select components such as motors, bearings, and sensors from trusted Chinese suppliers or top global brands based on their specific needs, guaranteeing reliable quality and high capacity.

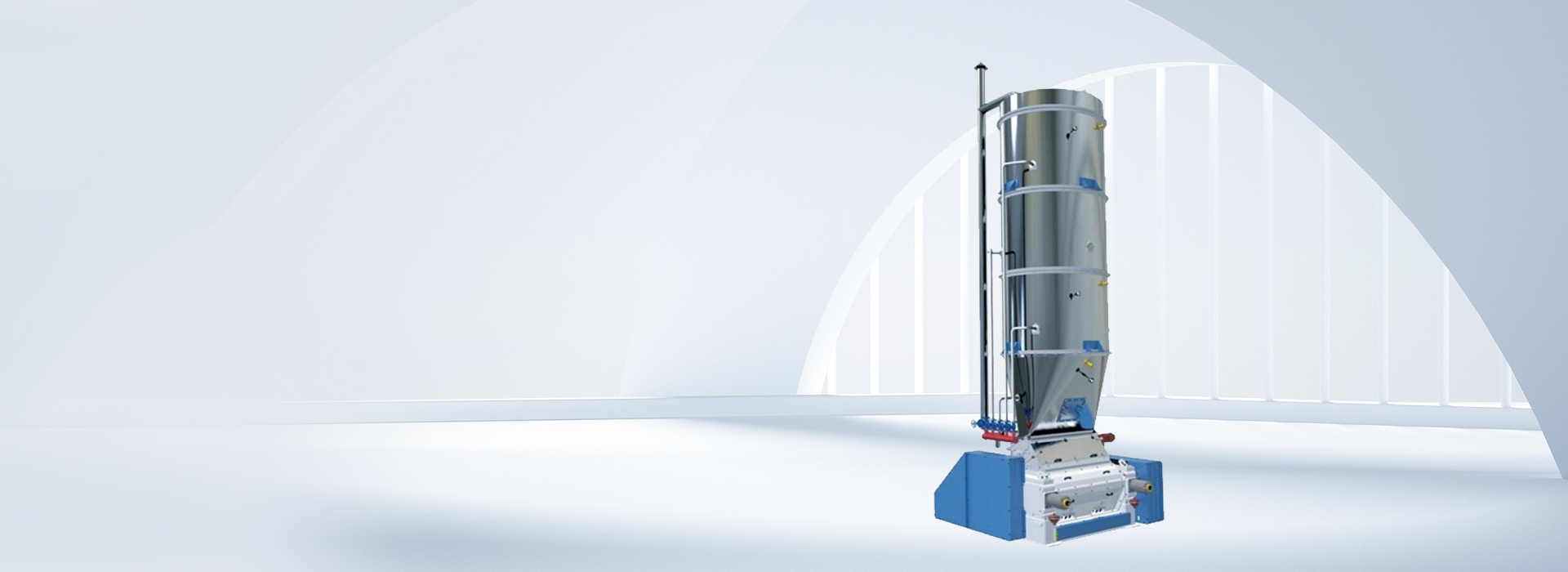

Flaking

Our advanced equipment, process design expertise, and skilled professionals are dedicated to meeting your specific flaking requirements. Designed for various sizes and production capacities, our products excel in processing corn steam flakes. The new generation of flaking mills offers reliable performance, ease of operation, and low maintenance costs, helping you boost production efficiency, minimize waste, and ensure high-quality output.

SCADA

FimCOS is a SCADA (Supervisory Control and Data Acquisition) system developed by FAMSUN. FimCOS has been successfully deployed in thousands of projects across feed processing, oil processing, new energy, and grain storage industries, delivering comprehensive automation control solutions to enhance production performance, ensure product quality, and maximize operational efficiency. Renowned for its comprehensive functionality, FimCOS offers:

• Robust customization to adapt to diverse industrial needs.

• Exceptional scalability for future growth.

• Superior compatibility with existing infrastructure.

• Remote iterative upgrades for seamless alignment with digital transformation initiatives.

Post Cooking

Our high-quality, reliable equipment, advanced process design, and experienced experts can meet your specific stabilization needs. Our product range is designed for premium aqua feed production in compound feed mills, effectively enhancing pellet water resistance and degree of gelatinization. Our products offer faster heating speeds, higher temperatures, shorter startup preheating times, and higher preheating temperatures. Featuring polished stainless steel plates, large cross-section tipping mechanisms, and steep tipping angles, our equipment ensures lower residue and less scorched feed. Additionally, the split maintenance doors promote air circulation, accelerate equipment cooling, and facilitate easier cleaning and maintenance.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN