Grinder VS Pulverizer: What's the Difference?

January 15, 2026

January 15, 2026

The demand for efficient size-reduction equipment is growing rapidly across industries. From food processing to pharmaceuticals, businesses need reliable tools to crush and refine materials. However, many people often confuse grinders and pulverizers, assuming they serve the same purpose.

Although both machines serve the same purpose, i.e., to pulverize materials into smaller pieces, they operate differently and produce distinct results. Understanding the difference between the two pieces of equipment helps you choose the right tool for your application. This, in turn, optimizes performance, improves energy efficiency, and enhances end-product quality.

What is A Grinder?

A grinder is a machine used to break down materials into smaller particles, typically achieving coarse-to-medium-size reduction. Unlike pulverizers, which produce ultra-fine powders, grinders are designed to deliver consistent, uniform particle sizes suitable for moderate processing needs. They operate through mechanical actions such as cutting, crushing or shearing using rotating blades or burrs.

Features of a Grinder

Grinders combine efficiency and versatility, offering a balance between coarse crushing and fine grinding machinery. Key features include:

Delivers consistent coarse to medium granules.

Processes large quantities quickly and efficiently.

Ensures uniform size and consistent texture.

Minimizes power use while maintaining performance.

What is A Pulverizer?

A pulverizer is a specialized grinding machine designed for reducing particles from fine to ultra-fine. It pulverizes solid materials into smooth, uniform powders using high-speed impact or compression. Compared to grinders, pulverizers achieve much finer output, making them ideal for applications that demand precision and texture control.

Key Features of A Pulverizer

Pulverizers represent the next level of fine grinding machinery, delivering superior fineness and control. Their main features include the following:

It produces exceptionally fine and uniform powders, ideal for delicate or precision applications.

It consumes more power as it operates at higher speeds and pressures to achieve fine-grinding results.

It handles heat-sensitive or brittle materials carefully, preventing damage or degradation.

Key Differences Between Grinder and Pulverizer

While both machines are used to pulverize materials, they differ significantly in performance, output, and industrial applications. Understanding these differences helps in selecting the right equipment for your production needs.

Particle Size: Grinders handle coarse to medium particle size reduction, while a pulverizer grinding machine can create fine, uniform powders for advanced use.

Energy Consumption: Pulverizers require more power than grinders because they operate at higher speeds and pressures to achieve ultra-fine grinding.

Applications: Grinders are used across general industries such as food and agriculture, whereas pulverizers are used in pharmaceuticals, chemicals, and minerals for fine processing.

Precision & Output: A pulverizer grinding machine delivers greater precision and consistency in particle size. Its ability to pulverize materials finely ensures smoother textures and higher-quality results, while grinders produce a coarser, less uniform output.

Maintenance & Cost: Pulverizers are more costly and complex to maintain, whereas grinders are simpler, cheaper, and easier to service.

Choosing The Right Equipment – Example from Feed Production

Selecting the right equipment depends on factors such as raw material type, target particle size, production volume, energy efficiency, and overall budget.

In the feed production industry, this choice directly impacts product quality and process efficiency. Grinders are best for bulk ingredients like corn, soybean meal, and grains, where coarse to medium particle size is sufficient for mixing and digestion.

In contrast, a pulverizer grinding machine is ideal for processing fine feed additives or specialty formulations. Its ability to pulverize materials into ultra-fine, uniform particles helps improve nutrient absorption, feed texture, and overall feed quality.

Choosing the right fine-grinding machinery ensures consistent results, optimized energy use, and improved performance.

Recommended Solutions for Efficient Feed Grinding and Pulverizing

When selecting equipment for size reduction, consider both coarse and ultra-fine options: the FAMSUN TPSG36 Series Roller Mill and the SWFL Series Pulverizer are excellent choices.

The TPSG36 Series Roller Mill is ideal for bulk coarse-to-medium grinding. It delivers a tight particle size distribution with minimal fine powder. This is achieved through large-diameter rolls and optimized nip angles that keep the proportion of <12-mesh material under 8%. It also features a modular design for easy scaling and quick roll-gap adjustment for different formulas.

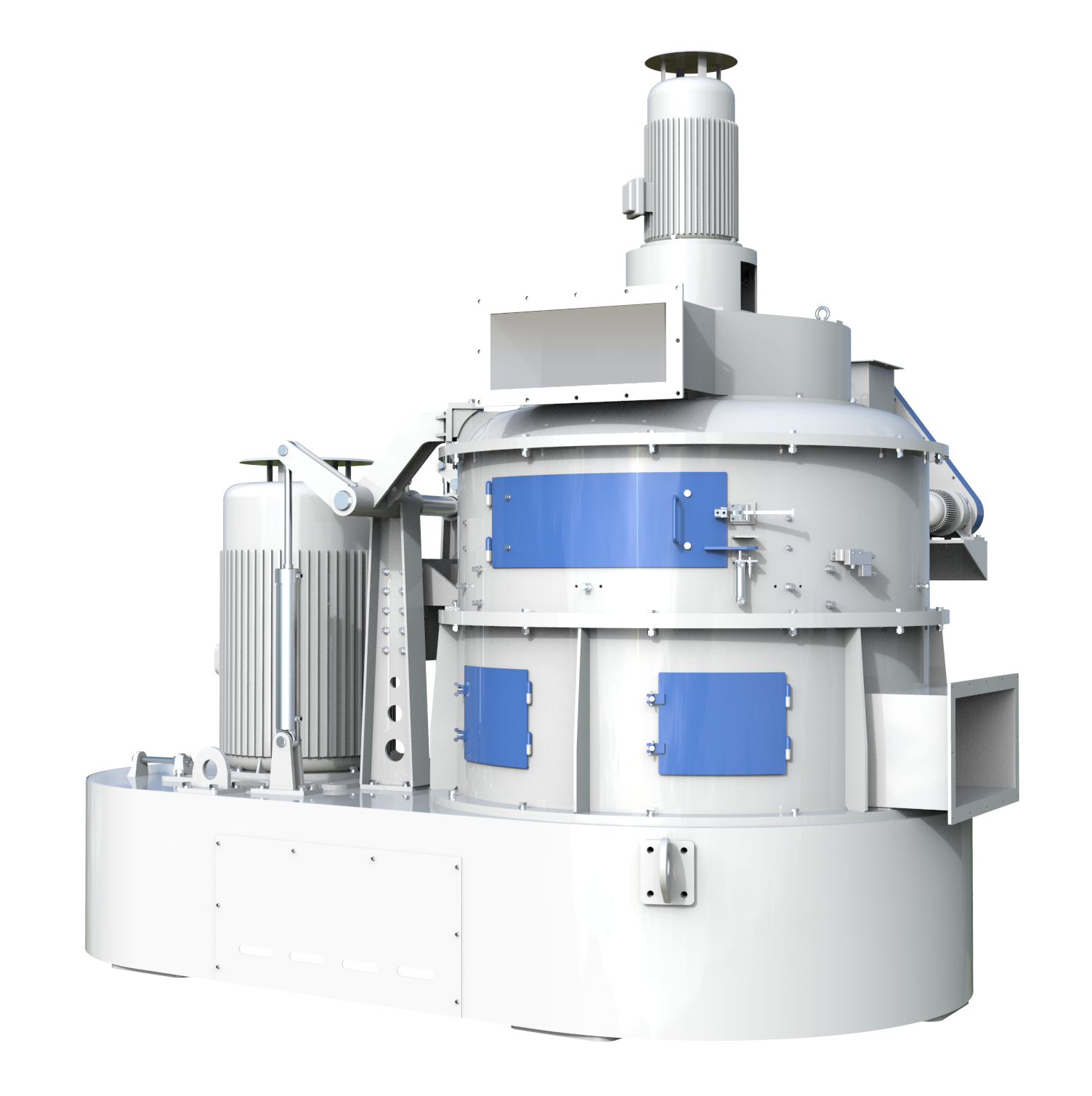

For fine-to-ultra-fine pulverizing, the SWFL Series Pulverizer stands out as a high-performance pulverizer grinding machine designed for applications requiring finely pulverized output. It achieves particle sizes ranging from 100 µm to 250 µm and offers precision control with VFD-driven impellers. The wear-resistant modular components ensure low downtime and high operating efficiency.

Together, these machines cover the full spectrum of size reduction—from major ingredient preparation to specialty fine grind applications—ensuring the right tool for each step.

Contact us to know which model suits your program best!

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN